Frequency Response Analysis (FRA), also known as Sweep Frequency Response Analysis (SFRA), is one of the most critical diagnostic tests performed during transformer commissioning and maintenance. This non-destructive testing technique helps ensure the mechanical integrity of transformers and identifies faults before they lead to catastrophic failures.

What is Frequency Response Analysis Test?

Frequency Response Analysis is a diagnostic technique that measures how a transformer’s winding responds to electrical signals across a wide frequency spectrum, typically ranging from 20 Hz to 2 MHz. The test operates by injecting a low-voltage sine wave signal into the transformer winding and measuring the attenuation (in decibels) of the transmitted signal at the other end of the winding. This response pattern, known as the ‘signature’ or ‘fingerprint’ of the transformer, becomes the benchmark for future reference.

The principle behind FRA is straightforward: the transformer’s frequency response is directly related to its RLC network structure (Resistance, Inductance, and Capacitance), which represents the physical geometry and construction of the transformer. Any changes in this physical structure—such as winding deformation or core movement—will result in variations in the frequency response.

Why is FRA Test Important?

FRA testing is essential for several reasons, particularly during pre-commissioning stages:

- Early Detection of Mechanical Damage: Transformers often experience mechanical stress during transportation and installation. The FRA test can detect core movement, winding deformation, hoop buckling, and other mechanical faults that might not be visible through conventional inspection.

- Assessment of Winding Integrity: The test is sensitive to various winding faults including partial winding collapse, displaced windings, and broken clamping structures. This sensitivity makes FRA particularly valuable for identifying inter-turn faults and winding deformations.

- Non-Destructive Testing: Unlike other diagnostic methods, FRA is completely non-intrusive and does not damage the transformer in any way, allowing it to be performed safely on in-service or newly commissioned units.

- Benchmark for Future Comparison: FRA signatures obtained at the factory or immediately after commissioning serve as a reference point for all future condition monitoring, allowing engineers to track changes in transformer health over time.

- Compliance with Standards: The test follows international standards including IEC 60076-18 and IEEE C57.149, ensuring standardized and reliable diagnostic capabilities.

SFRA Test Procedure for Transformer

Before conducting an FRA test, ensure the following prerequisites are met:

- Factory Test Report: Obtain the FRA test report from the transformer manufacturer in soft form (digital format). This baseline data is crucial for comparison purposes.

- Impact Recorder Data: Collect the impact recorder readings from the manufacturer. The FRA signatures should be analyzed in conjunction with these impact readings to get a complete picture of transportation effects.

- Test Equipment: Use an Automatic SFRA Test Kit equipped with application software for accurate and repeatable measurements. The kit should comply with relevant standards and include a data acquisition system with at least 12-bit resolution and 64K FFT data points for accurate frequency analysis.

- Documentation: Prepare all necessary test records, transformer specifications, and tap position information before commencing the test.

Step-by-Step FRA Test Procedure

Step 1: Transformer Preparation

- Ensure the transformer is completely de-energized and isolated from any external electrical connections

- Verify that all safety procedures are followed and the transformer is properly grounded

- Allow the transformer to stabilize at ambient temperature before testing

- Ensure the transformer has been fully assembled with oil filling completed, as per the manufacturing process

Step 2: Factory Reference Data Analysis

- Review the factory FRA test report to understand the baseline signature characteristics

- Identify the frequency response pattern that represents a healthy transformer

- Note any specific frequency bands of interest based on the transformer type and design

Step 3: Test Connection Setup

Connect the FRA test kit to the transformer following the proper terminal configuration:

For Power Transformers (Two-Winding):

- Test the high voltage (HV) winding separately from the low voltage (LV) winding

- Connect one terminal of the HV winding to the test kit output

- Connect the other HV terminal to the measurement input

- All other windings are left floating (electrically disconnected)

- Repeat the process for the LV winding

For Auto Transformers, more complex test combinations are required:

- Series Winding Tests: H1-X1, H2-X2, H3-X3 (all other terminals floating)

- Common Winding Tests: X1-H0X0, X2-H0X0, X3-H0X0

- Tertiary Winding Tests: Y1-Y3, Y2-Y1, Y3-Y2 (if applicable)

- Short Circuit Tests: Various combinations between H, X, and Y windings as specified

For Shunt Reactors:

- Conduct tests on H1-H0, H2-H0, and H3-H0 combinations

Step 4: Test on All Tap Positions

FRA must be performed at three specific tap positions:

- Maximum tap position (highest voltage setting)

- Normal tap position (rated voltage setting)

- Minimum tap position (lowest voltage setting)

This is essential because the frequency response characteristics change with tap position, and comparing results across all positions provides a comprehensive assessment.

Step 5: Signal Injection and Measurement

- Apply a 10V AC variable frequency signal to the transformer winding

- The frequency range should sweep from 20 Hz to 2 MHz

- The SFRA kit automatically injects the sine wave and measures the impedance response

- The system measures attenuation in decibels (dB) relative to the reference signal

- The test kit’s software calculates the frequency response characteristics using Fast Fourier Transform (FFT) algorithms with 256K or 1M data points for optimal frequency resolution

Step 6: Baseline Comparison

- Load the factory FRA signature into the analysis software

- Overlay the newly acquired FRA trace with the factory baseline

- Visually compare the frequency response patterns

- Use automated comparison algorithms to calculate statistical measures such as the sum of logarithmic errors and standard deviation

Step 7: Analysis and Interpretation

Compare the new FRA signature with the factory baseline using the following criteria:

- Matching Signatures: If the current FRA results closely match the factory results, the transformer has maintained its mechanical integrity during transportation and assembly

- Minor Deviations (< 5% deviation): May indicate minor mechanical changes that require monitoring but typically do not prevent commissioning

- Significant Deviations (5-10% deviation): Suggest potential winding displacement or core movement requiring detailed investigation and possible internal inspection

- Major Deviations (> 10% deviation): Indicate serious mechanical damage such as collapsed windings, core damage, or severe deformation, requiring the transformer to be returned to the manufacturer

Step 8: Impact Recorder Correlation

- Obtain the impact recorder report from the manufacturer

- Cross-reference the impact recorder data with FRA results

- If the transformer experienced significant mechanical impacts but FRA results are normal, the transformer may have inherent mechanical resilience

- If high-impact events correlate with FRA deviations, this confirms mechanical damage from transportation

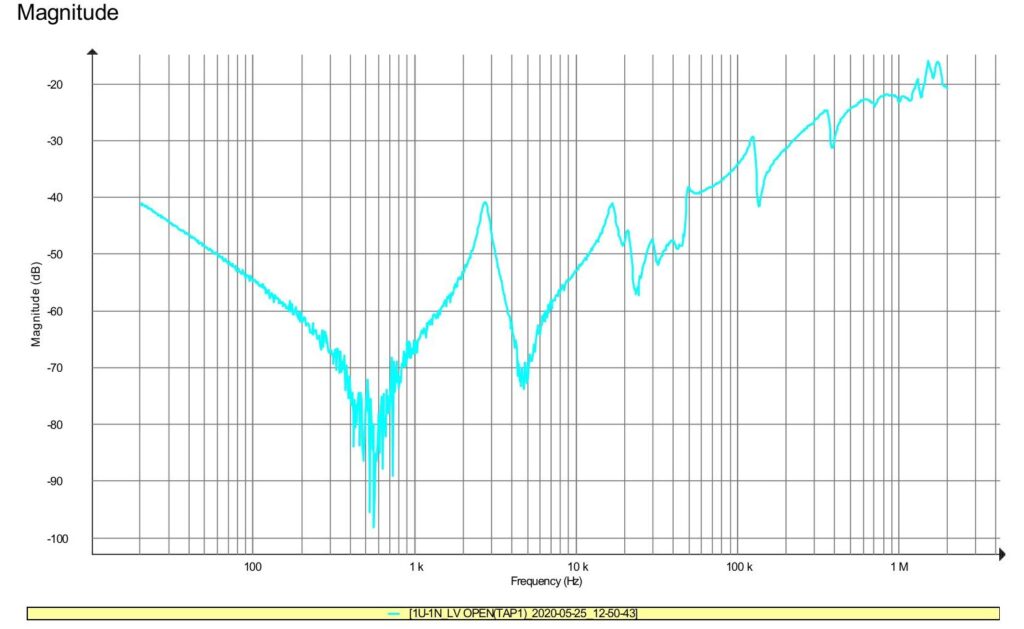

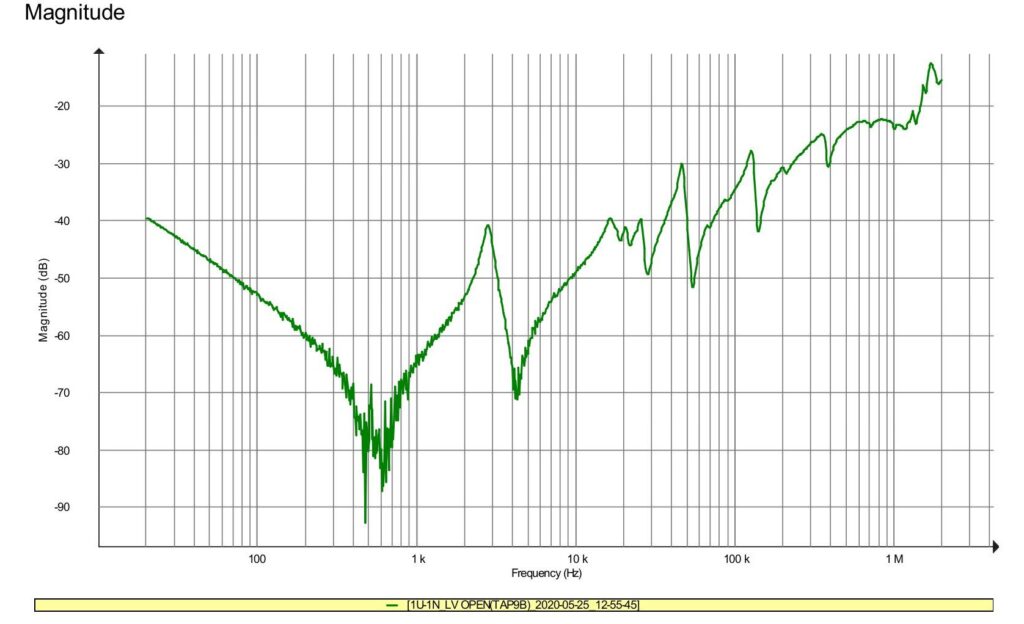

SFRA Test Signature Samples

Here are some SFRA Test signature samples for R Phase (HV to N) with three tap positions lowest, nominal and highest.

Equipment Required for FRA Testing

The essential equipment needed for conducting FRA tests includes:

Automatic SFRA Test Kit: A specialized instrument designed to perform frequency response analysis with built-in software for data capture and analysis. Modern SFRA kits include:

- Step voltage impulse generator with 350V peak output capacity

- Frequency sweep capability from 20 Hz to 2 MHz

- Minimum 12-bit resolution ADC

- FFT processor with 64K to 1M data points

- Automated trace comparison capabilities

Connecting Cables and Clamps: Properly rated cables for safe connection to transformer terminals, with low-resistance connections to ensure accurate measurements

Grounding Equipment: Safety grounding straps and cables to ensure transformer is properly earthed during testing

Computer with Analysis Software: Pre-loaded with FRA analysis software for data processing, baseline comparison, and report generation

Factory Test Reports: Digital copies of baseline FRA signatures from transformer manufacturing

SFRA Frequency Regions

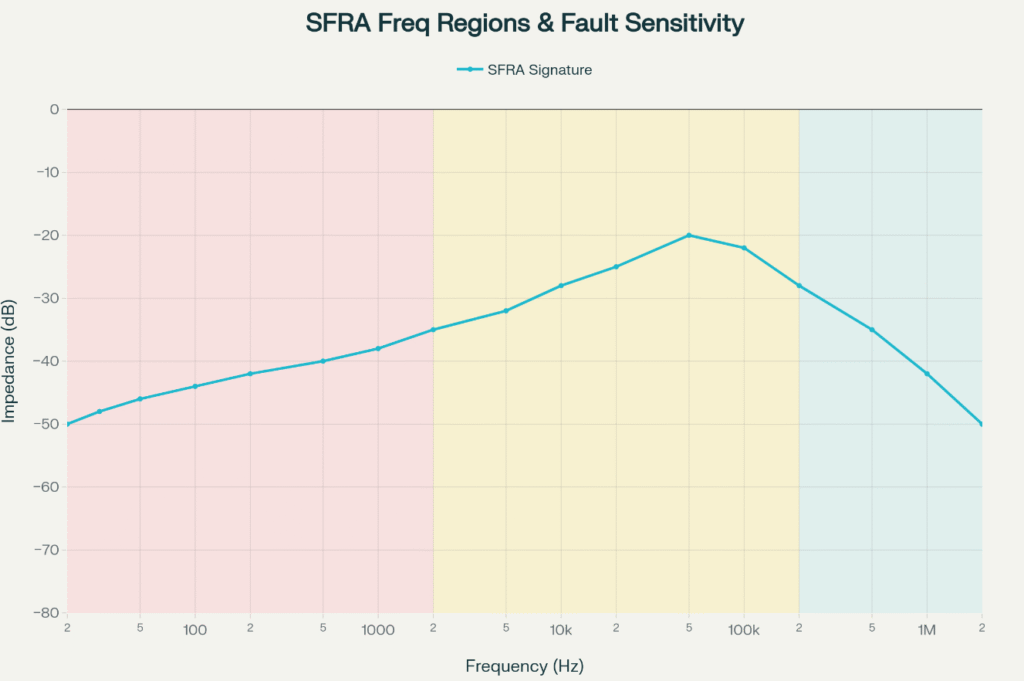

The Frequency Response Analysis (FRA) signature is divided into three distinct frequency regions, each providing diagnostic information about different aspects of transformer health and mechanical integrity.

The low-frequency region (20 Hz to 2 kHz) is primarily dominated by the transformer’s core and bulk inductance characteristics. This region is highly sensitive to core deformation, shorted laminations, open-circuit conditions in the windings, and residual magnetism issues. Changes in this region typically indicate major core problems or significant alterations to the magnetic structure, such as core displacement or loose clamping structures that affect the overall magnetizing inductance.

The mid-frequency region (2 kHz to 200 kHz) is the most critical and sensitive band for detecting transformer mechanical faults, as it is heavily influenced by the leakage inductance and inter-winding capacitance interactions. This band is exceptionally responsive to winding displacement, axial or radial buckling, and bulk deformations of the winding structure. When a winding shifts relative to another or experiences mechanical stress, the resonant peaks and valleys in this frequency range shift noticeably, producing dramatic and easily identifiable changes in the FRA signature.

Finally, the high-frequency region (200 kHz to 2 MHz) is sensitive to localized winding faults such as turn-to-turn shorts, insulation degradation, and fine structural details of conductor spacing and winding arrangement. This region reveals subtle defects in winding construction and insulation integrity that may not be visible in lower frequency bands.

Common Faults Detected by FRA Test

FRA testing can effectively identify the following transformer faults and abnormalities:

| Fault Type | FRA Signature Characteristic |

|---|---|

| Core Movement | Shifts in mid-frequency response (100 kHz – 1 MHz range) |

| Winding Deformation | Changes in high-frequency characteristics (> 1 MHz) |

| Winding Displacement | Deviation in resonance peaks and overall trace shape |

| Hoop Buckling | Significant changes in low to mid-frequency response |

| Faulty Core Ground | Abnormal impedance rise at specific frequency bands |

| Partial Winding Collapse | Sharp deviations and distortion in response traces |

| Broken Clamping Structure | Gradual shift in resonance patterns |

| Shorted Turns | Reduced impedance in affected frequency ranges |

| Open Windings | Extremely high impedance values |

When to Perform FRA Testing

FRA testing should be performed at the following critical stages:

- Pre-Commissioning: Immediately after transformer installation to establish baseline integrity

- Post-Transportation: After transporting the transformer to a new location to verify no damage occurred

- After Significant Impacts: Following earthquakes, accidents, or other mechanical events

- After Through-Faults: When the transformer experiences severe short-circuit current that could cause winding deformation

- Periodic Maintenance: At regular intervals during the transformer’s operational life to track condition degradation

- Before Major Repairs: To establish condition before any maintenance activities

Standards and Guidelines for FRA Testing

FRA testing is governed by international standards that define best practices and acceptance criteria:

IEC 60076-18: International standard specifically addressing mechanical integrity assessment of transformers through frequency response analysis measurement

IEEE C57.149: IEEE guide for the application and interpretation of frequency response analysis for oil-immersed transformers, providing comprehensive testing procedures and interpretation methodologies

Advantages and Limitations of FRA Test

Advantages:

- Non-destructive and non-intrusive testing method

- Highly sensitive to mechanical deformations and winding displacement

- Can be performed at any voltage rating

- Provides reliable information without dismantling the transformer

- Objective baseline for future condition monitoring

- Cost-effective compared to internal inspections

Limitations:

- Requires factory baseline data for meaningful comparison

- Requires experienced personnel for detailed interpretation

- Cannot identify electrical faults in isolation (must be combined with other tests)

- Environmental factors may slightly influence results

- Standardized acceptance criteria are still evolving in some regions

Conclusion

The Frequency Response Analysis test is an indispensable tool in transformer commissioning and maintenance workflows. By measuring the transformer’s electrical response across a broad frequency spectrum and comparing it with factory baseline data, engineers can confidently assess mechanical integrity and identify potential faults before they develop into serious problems. Following the systematic procedure outlined above, combined with proper equipment and careful data analysis, ensures that transformers are fit for service and will operate reliably throughout their operational life.

For comprehensive transformer testing protocols, consider also reviewing related pre-commissioning tests such as transformer polarity testing and winding resistance measurement, which complement the FRA test in providing a complete condition assessment of newly installed or relocated power transformers.