A Miniature Circuit Breaker (commonly known as MCB) is an automatic switching device that protects electrical circuits from damage caused by overcurrent or short circuit conditions. MCBs have replaced traditional fuses in modern electrical installations because they can be reset after tripping unlike fuses which need replacement. When the current flowing through a circuit exceeds the rated value, the MCB trips and disconnects the circuit from the power supply and prevents wire damage, fire hazards, and equipment failure.

MCBs are available in two main categories based on the type of current they handle: AC MCB and DC MCB. Both the DC and AC MCB serve the same basic purpose of circuit protection. However, they are designed differently to handle the unique characteristics of alternating current and direct current. Choosing the wrong type of MCB for your application can lead to safety hazards and equipment damage.

1. What is an AC MCB?

An AC MCB is specifically designed to protect circuits that operate on alternating current. Alternating current changes its direction periodically moving between positive and negative cycles. In most countries, the standard frequency is either 50 Hz or 60 Hz which means that the current changes direction 50 or 60 times per second.

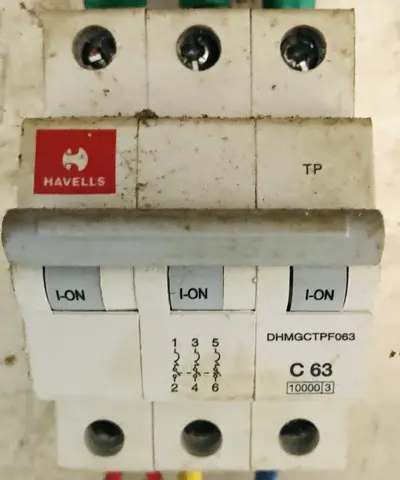

AC MCBs are the most common type found in residential, commercial, and industrial buildings. When you look at your home’s electrical distribution board, the circuit breakers installed there are almost always AC MCBs. These breakers are manufactured to work with single-phase (230V) and three-phase (400V) AC power systems.

For example, the MCB protecting your kitchen appliances, lighting circuits, or air conditioning units is an AC MCB. These circuit breakers are rated for specific voltage levels like 240V AC or 415V AC and current ratings ranging from 1A to 63A or higher.

2. What is a DC MCB?

A DC MCB is manufactured specifically for direct current applications. Unlike alternating current, direct current flows in only one direction and maintains a constant polarity. This characteristic makes DC circuits behave very differently from AC circuits especially during fault conditions.

DC MCBs are used in applications such as solar photovoltaic systems, battery storage systems, electric vehicles, telecommunications equipment, railway systems, and industrial DC motor drives.

For instance, in a solar power installation, the DC output from solar panels needs protection before it reaches the inverter. A DC MCB rated for 500V DC or 1000V DC is installed in the DC combiner box to protect the solar panel strings from overcurrent and short circuit faults.

3. Differences Between DC and AC MCB

The primary difference between DC and AC MCBs lies in their arc extinguishing capability. When an MCB interrupts a fault current, an electrical arc forms between its contacts. In AC circuits, this arc naturally extinguishes when the current crosses zero during each half cycle. However, in DC circuits, there is no zero-crossing point, which means the arc continues to burn until the breaker’s mechanism forcibly extinguishes it.

DC MCBs are built with larger arc chutes and specialized arc quenching chambers to handle persistent DC arcs. The physical size of a DC MCB is often larger than an equivalent AC MCB because of these additional components. The contact gap in DC MCBs is also wider to prevent arc re-striking after interruption.

Another major difference is polarity sensitivity. Many DC MCBs are polarity-sensitive meaning that the positive and negative terminals must be connected correctly. Incorrect polarity connection can result in improper arc extinction and MCB failure. On the other hand, AC MCBs are not polarity-sensitive since the current reverses direction continuously.

4. Construction Differences Between DC and AC MCB

4.1 Arc Chute Design

The arc chute in a DC MCB contains more splitter plates compared to an AC MCB. These plates help divide the arc into smaller segments, cooling it down and forcing it to extinguish. Some DC MCBs use permanent magnets near the arc chute to deflect the arc away from the contacts and into the extinguishing chamber.

4.2 Contact Gap

DC MCBs have a wider contact gap compared to AC MCBs. A larger gap reduces the chance of arc re-ignition after the contacts separate. In AC MCBs a smaller contact gap is sufficient because the natural zero-crossing of the current helps extinguish the arc.

4.3 Terminal Markings

DC MCBs often have clearly marked positive (+) and negative (-) terminals to indicate proper connection polarity. AC MCBs have line (L) and load terminals but no polarity markings since polarity doesn’t matter in AC circuits.

5. Voltage Ratings: DC MCB vs AC MCB

AC MCBs are rated for voltages like 230V AC, 240V AC, 400V AC, or 415V AC. These ratings represent the maximum operating voltage in alternating current systems.

DC MCBs have different voltage ratings that cannot be directly compared to AC ratings. Common DC voltage ratings include 24V DC, 48V DC, 125V DC, 250V DC, 500V DC, 800V DC, and 1000V DC or higher.

Important Note: You cannot use an AC MCB rated at 240V AC for a 240V DC application. The DC voltage rating is always lower than what you might expect because DC arcs are harder to extinguish. Some manufacturers provide dual ratings on their MCBs, such as “240V AC / 60V DC,” indicating the same breaker can handle 240 volts in AC but only 60 volts in DC.

6. Current Ratings and Breaking Capacity: DC MCB vs AC MCB

Both AC and DC MCBs are available in standard current ratings such as 1A, 2A, 4A, 6A, 10A, 16A, 20A, 25A, 32A, 40A, 50A, and 63A. Higher current ratings are also available for industrial applications.

Breaking Capacity (also called interrupting capacity or short circuit rating) is to the maximum fault current the MCB can safely interrupt. This is expressed in kilo-amperes (kA).

For AC MCBs, common breaking capacities are 6kA, 10kA, and 15kA at rated AC voltage.

For DC MCBs, the breaking capacity is usually lower at the same physical size because of the difficulty in extinguishing DC arcs. A DC MCB might have a breaking capacity of 6kA at 250V DC but only 3kA at 500V DC.

7. Trip Curves: B, C, and D Characteristics

Both AC and DC MCBs are available with different trip curves that determine how quickly they respond to overcurrent conditions.

- B Curve: Trips when the current reaches 3 to 5 times the rated current. Suitable for resistive loads with minimal inrush current. Used for lighting circuits, residential wiring, and small appliances.

- C Curve: Trips when the current reaches 5 to 10 times the rated current. Suitable for motors, transformers, and mixed loads with moderate inrush current. Most commonly used in general industrial and commercial applications.

- D Curve: Trips when the current reaches 10 to 20 times the rated current. Suitable for loads with high inrush current such as large motors, welding machines, and X-ray equipment.

8. Applications of AC MCB

AC MCBs are used in countless applications across residential, commercial, and industrial sectors:

8.1 Residential Applications

- Lighting circuits

- Socket outlet circuits

- Air conditioners

- Water heaters

- Kitchen appliances

- Washing machines

- Electric ovens

8.2 Commercial Applications

- Office lighting and power

- HVAC systems

- Elevator motor circuits

- Computer server rooms

- Retail store electrical systems

8.3 Industrial Applications

- Motor control centers

- Machinery protection

- Distribution panel boards

- Factory lighting

- Process equipment

9. Applications of DC MCB

DC MCBs have specialized applications in systems that operate on direct current:

9.2 Solar Photovoltaic Systems

- String protection in solar arrays

- DC combiner boxes

- Protection before inverters

- Battery charging circuits

9.3 Battery Systems

- Uninterruptible Power Supply (UPS)

- Energy storage systems

- Telecom battery backup

- Data center power systems

9.4 Transportation

- Electric vehicles

- Railway traction systems

- Marine electrical systems

- Electric buses and trucks

9.5 Industrial DC Applications

- Electroplating equipment

- DC motor drives

- Electrolysis processes

- DC welding machines

9.6 Telecommunications

- Base station power systems

- Signal equipment protection

- Network switch power supply

10. Standards and Certifications

MCBs must comply with international and regional standards to guarantee safe and reliable operation.

For AC MCB:

- IEC 60898 (International)

- EN 60898 (Europe)

- UL 489 (United States)

- IS 8828 (India)

For DC MCB:

- IEC 60947-2 (Industrial circuit breakers)

- IEC 60898-2 (DC MCBs for households)

- UL 489 with DC ratings

- EN 60947-2 (Europe)

11. Conclusion

Selecting the right type of MCB (whether AC or DC) is fundamental to electrical safety. While both types share similar protection functions, their internal design and arc extinguishing capabilities are quite different. Using an AC MCB in a DC circuit is dangerous and can result in fire, equipment damage, or injury.

12. Frequently Asked Questions (FAQs)

The main difference is in arc extinction. AC MCBs rely on natural zero-crossing of alternating current to extinguish arcs while DC MCBs use specialized arc chutes and magnetic blowout mechanisms because direct current has no zero-crossing point.

No, you should never use an AC MCB for DC circuits. AC MCBs cannot properly extinguish DC arcs, which can lead to overheating, fire, or explosion.

DC MCBs cost more because they require larger arc chutes, magnetic blowout coils, wider contact gaps, and more complex construction to handle DC arcs.

A polarity-sensitive DC MCB must be connected with the correct positive and negative terminals. Reversing the polarity can prevent proper arc extinction and cause MCB failure.

Yes, connecting multiple poles in series increases the effective DC voltage rating by adding more contact gaps. For example, a 2-pole MCB rated at 250V DC per pole can handle 500V DC when poles are connected in series.

Check the manufacturer’s datasheet or the markings on the MCB body. DC-rated MCBs display specific DC voltage ratings (like 250V DC or 500V DC) along with polarity markings (+ and -) on their terminals.