Circuit breakers play a major role in protecting electrical power systems from faults and abnormal conditions. Among the various types of circuit breakers used in the power industry, the Minimum Oil Circuit Breaker stands out as a reliable and efficient switching device. This type of circuit breaker uses oil as the arc quenching medium but requires a much smaller quantity compared to bulk oil circuit breakers.

In this technical guide, we will discuss everything about MOCBs including their construction, working principle, types, advantages, disadvantages, applications, and maintenance requirements.

1. What is a Minimum Oil Circuit Breaker (MOCB)?

A Minimum Oil Circuit Breaker is a type of high-voltage circuit breaker that uses transformer oil as the insulating and arc extinguishing medium. The term “minimum oil” refers to the fact that this circuit breaker uses oil only for arc extinction purposes. The oil is placed only around the contacts and inside the arc interrupting chamber. This design reduces the total oil requirement to about 10% to 15% of what a bulk oil circuit breaker would need.

The MOCB was developed to overcome the limitations of bulk oil circuit breakers. It offers better performance while using less oil. This makes it more economical and easier to maintain. MOCBs are commonly used in medium and high voltage applications ranging from 3.3 kV to 145 kV.

2. Historical Background of MOCB

The development of MOCBs began in the early 20th century when engineers started looking for ways to reduce the large quantities of oil used in bulk oil circuit breakers. The first commercial MOCBs appeared in the 1930s and gained popularity in Europe. Companies in Germany, France, and Switzerland pioneered the development of this technology.

Over the decades, the design of MOCBs has been refined and improved. Modern MOCBs feature advanced arc control devices and better insulating materials. Although newer technologies like SF6 circuit breakers and vacuum circuit breakers have emerged, MOCBs continue to be used in many power systems around the world.

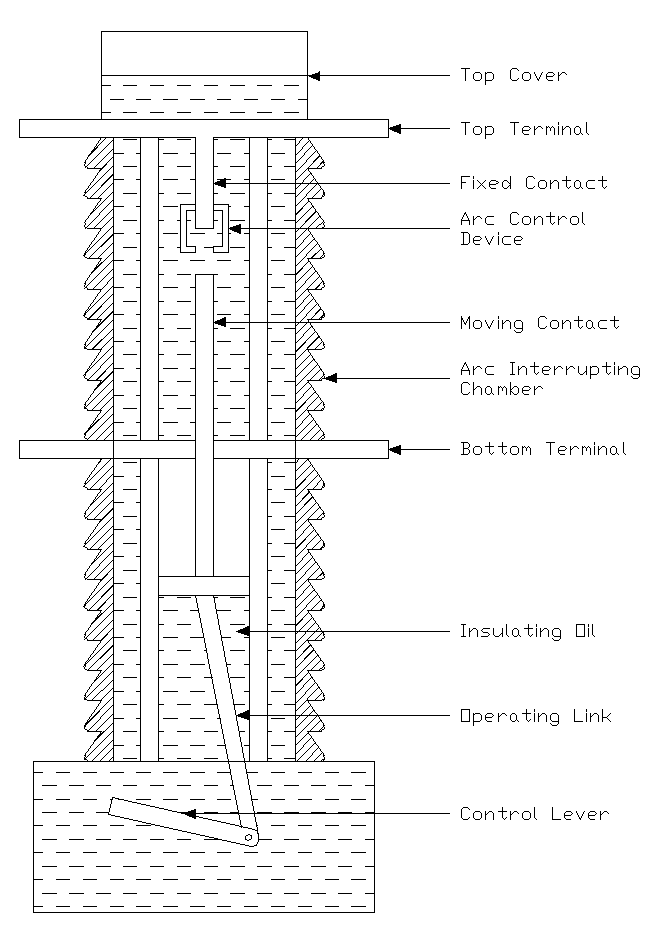

3. Construction of Minimum Oil Circuit Breaker

The construction of a MOCB consists of several important components that work together to provide reliable circuit interruption. Let us examine each component in detail.

3.1 Arc Interrupting Chamber

The arc interrupting chamber is the heart of the MOCB. This chamber contains the contacts and is filled with oil. When a fault occurs, the arc is drawn between the contacts within this chamber. The chamber is designed to withstand high pressure and temperature generated during arc interruption.

The arc interrupting chamber is made of insulating materials like bakelite, glass fiber reinforced epoxy, or porcelain. These materials provide excellent electrical insulation and mechanical strength. The chamber is designed to direct the flow of oil and gases in a controlled manner.

3.2 Moving and Fixed Contacts

The MOCB has two types of contacts: fixed contacts and moving contacts. The fixed contacts are stationary and mounted inside the arc interrupting chamber. The moving contacts are attached to a mechanism that allows them to move up and down.

When the circuit breaker is in the closed position, the moving contacts touch the fixed contacts. This creates a continuous electrical path. When the circuit breaker opens, the moving contacts move away from the fixed contacts. This action breaks the circuit and an arc is formed between the separating contacts.

3.3 Arc Control Device

The arc control device is a special component that helps in efficient arc extinction. It is placed around the contacts inside the interrupting chamber. The arc control device forces the arc to pass through a series of narrow channels or vents. This increases the contact between the arc and the oil.

There are different types of arc control devices used in MOCBs:

- Cross Blast Type: In this design, oil is forced to flow across the arc at right angles. This provides efficient cooling of the arc.

- Axial Blast Type: Here, the oil flows along the axis of the arc. The gas generated by oil decomposition helps in arc extinction.

- Self-Compensating Type: This design combines the features of both cross blast and axial blast types. It provides good performance under different fault conditions.

3.4 Oil Tank

The oil tank in a MOCB is much smaller compared to a bulk oil circuit breaker. The tank contains the oil required for arc extinction and insulation. It is designed to withstand the pressure generated during fault interruption.

The oil tank is usually made of steel or other strong metal. It is often cylindrical or rectangular in shape. The tank includes a filling plug for adding oil and a drain plug for removing oil during maintenance.

3.5 Supporting Structure

The supporting structure holds all the components of the MOCB in place. It consists of a frame made of steel or other metal. The supporting structure must be strong enough to withstand the mechanical forces generated during circuit breaker operation.

For outdoor installations, the supporting structure is designed to withstand wind, rain, and other environmental factors. The structure also includes mounting points for connecting the circuit breaker to the switchgear or substation equipment.

3.6 Operating Mechanism

The operating mechanism provides the force needed to open and close the circuit breaker contacts. There are several types of operating mechanisms used in MOCBs:

- Spring-Operated Mechanism: This type uses charged springs to provide the opening and closing force. The springs are charged manually or by a motor.

- Solenoid Mechanism: An electromagnetic solenoid provides the operating force. This mechanism offers fast operation but requires a reliable power supply.

- Pneumatic Mechanism: Compressed air provides the operating force. This type is often used for large, high-voltage MOCBs.

3.7 Bushings

Bushings are used to bring the electrical connections out of the circuit breaker tank. They provide insulation between the live conductors and the grounded tank. Bushings are made of porcelain or epoxy resin.

The bushings must be designed to handle the rated voltage and current of the circuit breaker. They must also withstand the thermal stresses caused by load current and fault current.

4. Working Principle of MOCB

The working principle of a MOCB is based on arc extinction using oil. When the circuit breaker contacts separate during a fault, an arc is formed between them. This arc must be extinguished quickly to interrupt the fault current.

4.1 Arc Formation

When a fault occurs in the power system, the protection relay sends a trip signal to the circuit breaker. The operating mechanism responds by separating the moving contact from the fixed contact. As the contacts separate, the fault current continues to flow through the small gap between them. This causes an arc to form.

The arc is a channel of ionized gas that conducts electricity. The temperature of the arc can reach several thousand degrees Celsius. This extreme temperature causes the surrounding oil to vaporize and decompose.

4.2 Oil Decomposition

When the oil is exposed to the high temperature of the arc, it decomposes into hydrogen, carbon, carbon monoxide, and other gases. Hydrogen is the main gas produced during oil decomposition. It has excellent arc-quenching properties.

The hydrogen gas surrounds the arc and helps in cooling it down. The high thermal conductivity of hydrogen removes heat from the arc rapidly. This causes the arc to become unstable and eventually extinguish.

4.3 Arc Extinction

The arc control device plays a major role in the arc extinction process. It directs the flow of oil and gases around the arc. The turbulent flow of oil and gases increases the rate of heat removal from the arc.

As the contacts continue to separate, the arc becomes longer and more difficult to sustain. The combination of hydrogen gas production, oil flow, and increasing contact gap leads to arc extinction. The arc is usually extinguished when the current passes through zero during the AC cycle.

4.4 Current Zero Interruption

In AC circuits, the current naturally passes through zero twice during each cycle. At the current zero point, the arc briefly loses its conductivity. If the arc cooling is sufficient at this moment, the arc will not reignite.

The MOCB is designed to provide maximum cooling at the current zero point. This allows the circuit breaker to interrupt the fault current successfully. After the arc is extinguished, the dielectric strength of the oil recovers and prevents any further current flow.

5. Types of Minimum Oil Circuit Breakers

MOCBs can be classified into different types based on their voltage rating, design features, and installation location.

5.1 Based on Voltage Rating

Medium Voltage MOCBs: These circuit breakers are designed for voltages ranging from 3.3 kV to 33 kV. They are commonly used in industrial plants, distribution substations, and commercial buildings. Medium voltage MOCBs are compact and require relatively small quantities of oil.

High Voltage MOCBs: These circuit breakers are designed for voltages above 33 kV up to 145 kV. They are used in transmission substations and large power plants. High voltage MOCBs have multiple arc interrupting chambers connected in series to handle the higher voltage.

5.2 Based on Installation Location

Indoor MOCBs: These circuit breakers are designed for installation inside buildings or enclosed switchgear rooms. Indoor MOCBs have simpler construction since they are protected from weather conditions. They are commonly used in factories, commercial buildings, and indoor substations.

Outdoor MOCBs: These circuit breakers are designed for installation in open areas. Outdoor MOCBs have weatherproof enclosures to protect them from rain, snow, dust, and other environmental factors. They are commonly used in transmission and distribution substations.

5.3 Based on Number of Breaks

Single Break MOCBs: These circuit breakers have one set of contacts per phase. The entire voltage appears across a single contact gap. Single break MOCBs are simpler and more economical but are limited to lower voltages.

Double Break MOCBs: These circuit breakers have two sets of contacts per phase connected in series. The voltage is divided between two contact gaps. Double break MOCBs can handle higher voltages than single break types.

Multi-Break MOCBs: These circuit breakers have multiple contact gaps connected in series. They are used for very high voltage applications where more than two breaks are needed to handle the voltage stress.

6. Advantages of Minimum Oil Circuit Breaker

MOCBs offer several advantages that have made them popular in the power industry.

- Reduced Oil Quantity: The most obvious advantage of a MOCB is the reduced oil requirement. It uses only about 10% to 15% of the oil that a bulk oil circuit breaker would need.

- Lower Cost: The reduced oil quantity translates to lower costs. Oil is expensive and requires proper storage and handling. By using less oil, MOCBs reduce the initial cost of installation.

- Smaller Size: MOCBs are more compact than bulk oil circuit breakers. The smaller tank size reduces the floor space requirement.

- Easier Maintenance: The smaller oil quantity makes maintenance easier. Oil testing and replacement can be done more quickly. The circuit breaker can be opened and inspected with less effort. This reduces downtime and maintenance costs.

- Better Arc Extinction: The arc control device in a MOCB provides more controlled arc extinction compared to bulk oil circuit breakers. The directed flow of oil and gases ensures efficient cooling of the arc. This results in faster and more reliable fault current interruption.

- Reduced Fire Risk: With less oil in the circuit breaker, the fire risk is reduced. In case of a severe fault, the smaller oil quantity limits the amount of fuel available for a fire. This is an important safety consideration in substations and industrial plants.

- Suitable for Repeated Operations: MOCBs can handle repeated switching operations without significant degradation. The arc control device and chamber design allow for efficient arc extinction even during frequent operations. This makes MOCBs suitable for applications with many switching cycles.

7. Disadvantages of Minimum Oil Circuit Breaker

Despite their advantages, MOCBs also have some limitations that must be considered.

- Oil Maintenance Requirements: Although MOCBs use less oil, the oil still requires regular testing and maintenance. The oil must be checked for dielectric strength, acidity, and contamination. Deteriorated oil must be filtered or replaced. This adds to the maintenance workload.

- Fire Hazard: While the fire risk is lower than bulk oil circuit breakers, oil is still flammable. In case of a severe internal fault, the oil can ignite and cause a fire. Special fire protection measures may be needed in sensitive locations.

- Environmental Concerns: Oil leakage from MOCBs can contaminate soil and groundwater. Special containment measures may be required to prevent environmental damage. Disposal of used oil must be done according to environmental regulations.

- Limited Short Circuit Capacity: MOCBs have limited interrupting capacity compared to some modern circuit breaker types. For very high fault current applications, SF6 or vacuum circuit breakers may be more suitable.

- Slower Operation: MOCBs generally have slower operating speeds compared to vacuum or SF6 circuit breakers. The time required to extinguish the arc is longer. This can be a limitation in applications requiring very fast fault clearance.

- Deterioration Over Time: The oil in an MOCB deteriorates over time due to electrical and thermal stresses. The arc causes chemical changes in the oil that reduce its insulating and arc-quenching properties. Regular oil testing and replacement are necessary to maintain reliable operation.

- Not Suitable for Very High Voltages: For very high voltage applications above 145 kV, MOCBs become impractical. The number of arc interrupting chambers required becomes too large. SF6 circuit breakers are preferred for extra high voltage applications.

8. Applications of Minimum Oil Circuit Breaker

MOCBs are used in various applications across the power industry. Here are some common applications.

8.1 Power Substations

MOCBs are widely used in transmission and distribution substations. They protect transformers, bus bars, and feeder circuits from faults. In a 66 kV substation, for example, MOCBs might be used to protect the incoming lines and outgoing feeders.

8.2 Industrial Plants

Large industrial plants use MOCBs in their electrical distribution systems. Manufacturing facilities, steel plants, refineries, and chemical plants commonly use MOCBs. They protect motors, generators, and other electrical equipment.

8.3 Power Generating Stations

Power plants use MOCBs in their generating and auxiliary systems. They protect generators, unit transformers, and auxiliary equipment. Both thermal and hydroelectric power plants use MOCBs.

8.4 Railway Traction Systems

Electric railway systems use MOCBs in their traction substations. They protect the traction transformers and feeding equipment. MOCBs provide reliable protection for the railway power supply.

8.5 Commercial Buildings

Large commercial complexes and high-rise buildings use MOCBs in their high voltage distribution systems. They provide protection for the main incoming supply and distribution transformers.

8.6 Mining Operations

Mining operations use MOCBs in their electrical distribution systems. They provide protection for underground and surface mining equipment. The rugged construction of MOCBs makes them suitable for the demanding mining environment.

9. Comparison of MOCB with Other Circuit Breakers

Let us compare MOCBs with other types of circuit breakers to understand their relative strengths and weaknesses.

9.1 MOCB vs Bulk Oil Circuit Breaker (BOCB)

The main difference is the quantity of oil used. BOCBs use large amounts of oil for both insulation and arc extinction. MOCBs use oil only for arc extinction. MOCBs are more compact, lighter, and require less maintenance. However, BOCBs are simpler in construction and may be more suitable for some applications.

9.2 MOCB vs SF6 Circuit Breaker

SF6 circuit breakers use sulfur hexafluoride gas as the arc extinction medium. SF6 has superior arc-quenching properties compared to oil. SF6 circuit breakers are smaller, require less maintenance, and have higher interrupting capacity. However, SF6 is a greenhouse gas with high global warming potential. MOCBs use oil which is more environmentally friendly in this regard.

9.3 MOCB vs Vacuum Circuit Breaker (VCB)

Vacuum circuit breakers use a vacuum chamber to extinguish the arc. They are compact, require very little maintenance, and have long service life. VCBs are commonly used for medium voltage applications up to 36 kV. For higher voltages, MOCBs may be more practical than VCBs.

9.4 MOCB vs Air Blast Circuit Breaker

Air blast circuit breakers use compressed air to extinguish the arc. They can handle very high voltages and fault currents. However, they require a compressed air system which adds complexity and cost. MOCBs are simpler and do not require an air supply.

10. Maintenance of Minimum Oil Circuit Breaker

Regular maintenance is necessary to keep an MOCB in good working condition. Here are the main maintenance activities.

10.1 Oil Testing

The oil in an MOCB should be tested regularly. The main tests include:

- Dielectric Strength Test: This test measures the ability of the oil to withstand electrical stress. The oil should have a minimum breakdown voltage of 30 kV for a 2.5 mm gap.

- Acidity Test: This test measures the acid content in the oil. High acidity indicates oil degradation and can damage the circuit breaker components.

- Moisture Content Test: Water in the oil reduces its insulating properties. The moisture content should be kept below specified limits.

- Dissolved Gas Analysis: This test detects gases dissolved in the oil. The presence of certain gases can indicate problems inside the circuit breaker.

10.2 Contact Inspection

The contacts should be inspected periodically. Look for signs of wear, pitting, or burning on the contact surfaces. Worn contacts should be replaced to maintain reliable operation.

The contact gap and contact pressure should be checked and adjusted if necessary. Proper contact pressure is needed for low resistance in the closed position.

10.3 Arc Control Device Inspection

The arc control device should be inspected for damage. The vents and channels should be clear of carbon deposits. Damaged arc control devices should be replaced.

10.4 Mechanism Servicing

The operating mechanism should be inspected and lubricated. Check for wear in bearings, linkages, and other moving parts. The mechanism should operate smoothly without binding or sticking.

Springs should be checked for proper tension and condition. Weak or broken springs should be replaced.

10.5 Bushing Inspection

The bushings should be inspected for cracks, chips, or contamination. Clean the bushing surfaces to remove dust and dirt. Check the bushing connections for tightness.

10.6 General Inspection

Check the circuit breaker tank for oil leaks. Tighten any loose bolts or fittings. Inspect gaskets and seals for condition.

Check the earthing connections for tightness. Verify that all safety devices are functioning properly.

11. Testing of MOCB

Several tests are performed on MOCBs to verify their performance and condition.

11.1 Routine Tests

Routine tests are performed on every circuit breaker during manufacturing. These include:

- Power frequency withstand test

- Main circuit resistance test

- Mechanical operation test

- Auxiliary circuit tests

11.2 Type Tests

Type tests are performed on sample circuit breakers to verify the design. These include:

- Short circuit breaking and making tests

- Temperature rise test

- Impulse voltage withstand test

- Mechanical endurance test

11.3 Site Tests

After installation, certain tests are performed at the site. These include:

- Insulation resistance test

- Contact resistance test

- Timing test

- Functional test of protection and control circuits

12. Conclusion

The Minimum Oil Circuit Breaker remains an important component in electrical power systems around the world. Although newer technologies have emerged, MOCBs continue to provide reliable protection for medium and high voltage applications. Understanding the construction, working principle, and maintenance requirements of MOCBs is valuable knowledge for electrical engineers and technicians.

13. Frequently Asked Questions (FAQs)

The main difference is the quantity of oil used. A Bulk Oil Circuit Breaker uses oil for both insulation and arc extinction. The entire circuit breaker is immersed in a large tank of oil. A Minimum Oil Circuit Breaker uses oil only in the arc interrupting chamber. The supporting structure uses air or solid insulation.

MOCBs use transformer oil, which is a highly refined mineral oil. Common specifications for transformer oil include IS 335 in India and IEC 60296 internationally.

Hydrogen gas is produced when the transformer oil decomposes due to the high temperature of the arc. Hydrogen has several properties that make it excellent for arc extinction. It has high thermal conductivity which helps cool the arc quickly. It also has low molecular weight which allows it to diffuse rapidly into the arc column. These properties help deionize the arc and extinguish it.

The arc control device is a component that controls the flow of oil and gases around the arc. It directs the oil to flow across or along the arc in a controlled manner. This increases the contact between the arc and the cooling medium. The arc control device improves the arc extinction efficiency and allows the circuit breaker to interrupt higher fault currents.

The oil should be tested at regular intervals depending on the operating conditions. For general guidance, oil testing should be done at least once a year. In polluted or demanding environments, more frequent testing may be needed.

Yes, MOCBs can be used for generator protection. They are commonly used in power plants to protect generators from faults.