The Tan Delta Test (also known as Dissipation Factor Test or Dielectric Loss Test) is one of the most sensitive and reliable diagnostic methods used to assess the quality and condition of transformer oil. This test measures the dielectric losses within the insulating oil by determining the tangent of the loss angle (δ), which indicates the oil’s ability to store and release electrical energy.

A low tan delta value signifies high-quality oil with minimal impurities, while an elevated value signifies deterioration, contamination, or moisture ingress that can compromise the transformer’s insulation system.

The breakdown voltage test only detect severe contamination, however, the tan delta test is highly sensitive to even minor changes in oil condition, making it an indispensable tool for preventive maintenance programs.

The Basic Principle of Tan Delta Test

What is Dielectric Loss?

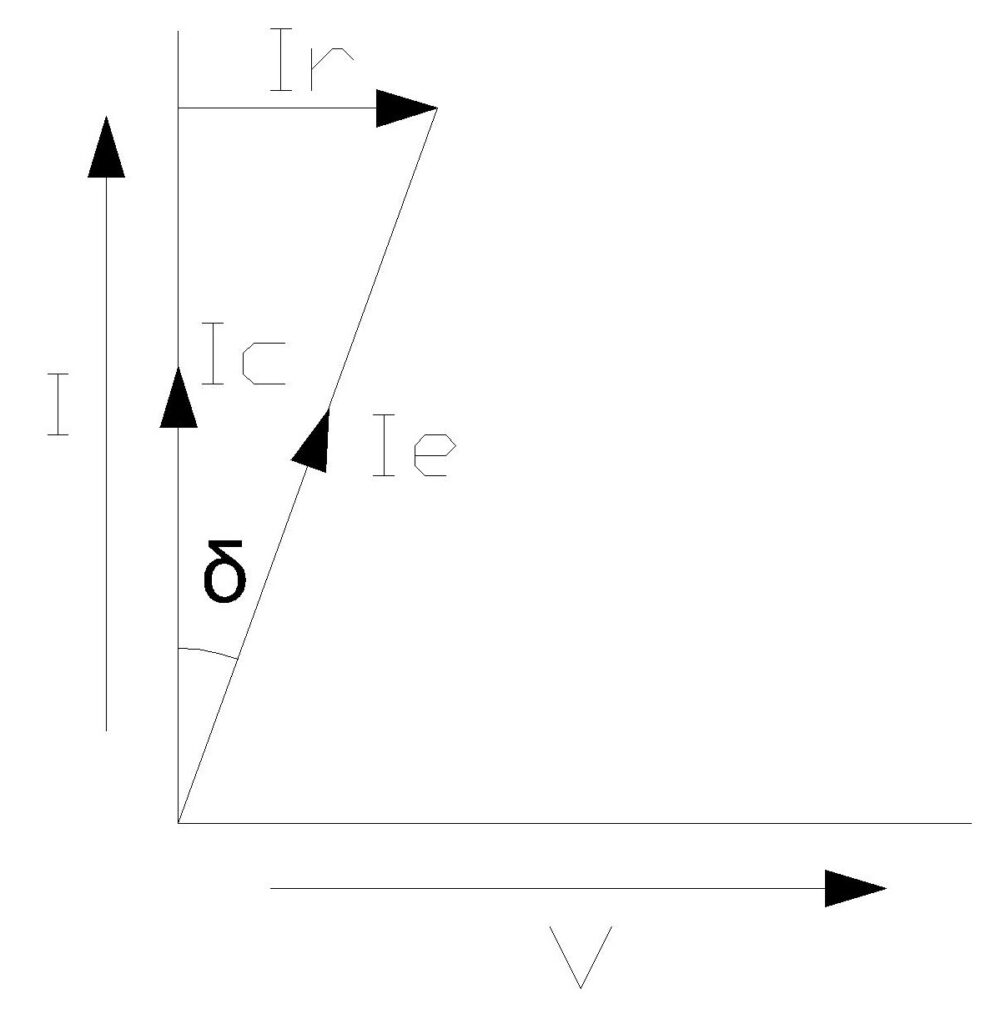

When alternating current (AC) voltage is applied across transformer oil, the oil experiences energy loss due to two primary mechanisms: electrical polarization and conductance. In an ideal insulator with 100% purity, the current passing through would be purely capacitive, leading the applied voltage by exactly 90 degrees. However, real-world transformer oil contains impurities such as moisture, dissolved gases, oxidation by-products, and polar contaminants that introduce a resistive component to the current flow.

This resistive component causes the phase angle between the current and voltage to deviate from the ideal 90 degrees. The complementary angle to this phase difference is called the dielectric loss angle (δ), and its tangent value (tan δ) represents the ratio of the resistive current component to the capacitive current component.

The tan delta test specifically measures this ratio, providing a direct indication of the energy dissipated as heat within the oil, which correlates strongly with the degree of contamination and deterioration.

The Physics Behind Tan Delta

The mathematical relationship for tan delta is expressed as:

\(\tan \delta = \frac{I_r}{I_c}\)

where \((I_r)\) is the resistive (loss) component of current and \((I_c)\) is the capacitive (charging) component. For high-quality insulating oils, this ratio remains extremely small (typically less than 0.005 or 0.5%). As the oil ages or becomes contaminated, the resistive component increases significantly, causing the tan delta value to rise.

The dissipation factor directly represents the power loss in the oil, with higher tan delta values indicating greater energy dissipation as heat. This heat generation can create a vicious cycle: increased dielectric loss produces more heat, which further accelerates oil degradation and increases tan delta values, potentially leading to insulation breakdown at defect points.

Why Tan Delta Test is Critical for Transformer Oil

Sensitivity to Contamination

The tan delta test exhibits remarkable sensitivity to various forms of oil contamination, making it superior to many other oil quality assessment methods. When transformer oil deteriorates or becomes polluted, the tan delta value can increase by more than ten times its original value. This heightened sensitivity allows maintenance teams to detect problems at very early stages, long before they show as operational issues.

Moisture ingress represents one of the most common and dangerous forms of contamination in transformer systems. Even small amounts of dissolved water increase the tan delta value because water molecules are highly polar and contribute significantly to dielectric losses. Similarly, contamination from acids, sludge, particles, metal compounds, aldehydes, ketones, and alcohols all elevate the dissipation factor by introducing conductive pathways through the oil.

Early Warning System

The tan delta test functions as an early warning system for transformer health management. By monitoring trends in tan delta values over time, engineers can identify gradual deterioration patterns that indicate aging insulation, oxidation, or contamination before these conditions lead to equipment failure. This predictive capability enables proactive maintenance strategies, allowing for oil reconditioning, filtration, or complete replacement during scheduled outages rather than emergency situations.

Test Standards and Specifications

International Testing Standards

Tan delta testing of transformer oil follows well-established international standards that ensure consistency, accuracy, and reliability across different testing facilities and equipment.

The two primary standards governing this test are:

- ASTM D924 – Standard Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical Insulating Liquids. This American standard specifies test procedures at 100°C for acceptance testing, though it allows testing at lower temperatures (25°C or room temperature) for routine evaluations.

- IEC 60247 – Measurement of Relative Permittivity, Dielectric Dissipation Factor (tan δ), and DC Resistivity. This international standard is widely adopted globally and also specifies testing at elevated temperatures (90°C or 100°C) to simulate operating conditions, with provisions for ambient temperature testing.

Additional relevant standards include IEC 61620, BS 5737, JIS C2101, VDE 0380-2, and IS 6262, which are adopted by various countries and regions.

Acceptable Tan Delta Limits

The acceptable tan delta values for transformer oil vary depending on the voltage class of the transformer and the oil condition. The following table presents the standard limits:

| Voltage Level | Maximum Tan Delta Value | Remarks |

|---|---|---|

| ≤ 330 kV | ≤ 0.040 (4.0%) | For lower voltage transformers |

| ≥ 500 kV | ≤ 0.020 (2.0%) | For ultra-high voltage transformers |

| General (at 20°C) | ≤ 0.005 (0.5%) | Standard acceptable limit for bushings/windings |

For modern oil-filled power transformers, the insulation power factor should typically be 0.7% or lower at 20°C. However, older transformers or certain types of distribution transformers may exhibit power factors exceeding 0.7% while still being acceptable

Tan Delta Test Equipment and Setup

Test Equipment Components

A complete tan delta test system for transformer oil consists of several key components that work together to provide accurate measurements:

- Tan Delta Bridge/Analyzer: The core measurement unit that applies test voltage and measures the phase relationship between voltage and current to calculate tan delta values. Modern instruments offer high accuracy (±1% for capacitance, 1×10⁻⁴ to 1×10⁻⁶ for tan delta) with digital displays and automated data recording.

- Oil Test Cell: A specialized container designed according to IEC 60247 specifications with precisely positioned electrodes (typically 2mm gap) and a capacity of 40-60ml. The test cell must have extremely low inherent capacitance (around 60pF±3pF) and dissipation factor (less than 0.0001) when empty to ensure accurate measurements.

- Temperature Control System: Sophisticated test equipment includes built-in inductive heating systems with PID temperature control algorithms for precise temperature regulation (±1°C accuracy).

- High Voltage Source: Provides the AC test voltage, typically ranging from 500V to 2000V for oil testing.

- Data Acquisition and Analysis System: Features touchscreen interfaces, automated measurement sequences, and computer connectivity for data management.

Test Cell Preparation

Proper preparation of the test cell is critical for accurate results. The test cell, electrodes, glass cover, and stirring rod must be thoroughly cleaned and dried to remove all traces of moisture, fibers, oil residue, and other contaminants. The electrode gap must be precisely set with a standard gauge, typically to 2.5mm ± 0.1mm. Before testing, the cell should be rinsed three times with the oil sample to avoid cross-contamination.

Step-by-Step Test Procedure

Oil Sampling Process

The oil sample must be extracted from the transformer drain valve, which should be cleaned, dried, and flushed before sampling to prevent contamination. Ensure oil temperature stabilization at 27°C ± 2°C prior to testing. Avoid air bubbles in the sample using proper techniques.

Test Execution Steps

| Step No. | Test Procedure | Key Points |

|---|---|---|

| 1 | Isolate transformer and de-energize completely | Ensure isolation from HV and LV sides |

| 2 | Take oil sample from drain valve | Ensure oil is at stable temperature |

| 3 | Clean and dry the test cell thoroughly | Remove moisture, fibers, and residue |

| 4 | Fill test cell with oil sample (40-60ml) | Avoid air entrapment while filling |

| 5 | Set temperature (25°C, or 90°C for high temp) | Allow stabilization (15-30 min) |

| 6 | Apply test voltage (500V-2000V AC typical) | Start low, increase gradually |

| 7 | Measure and record tan delta and capacitance | Note ambient temperature and humidity |

Pour oil slowly along a glass rod to minimize bubbles. Use automated equipment for dual-frequency testing for improved accuracy. Record all parameters and test details for trend analysis.

Factors Affecting Tan Delta Values

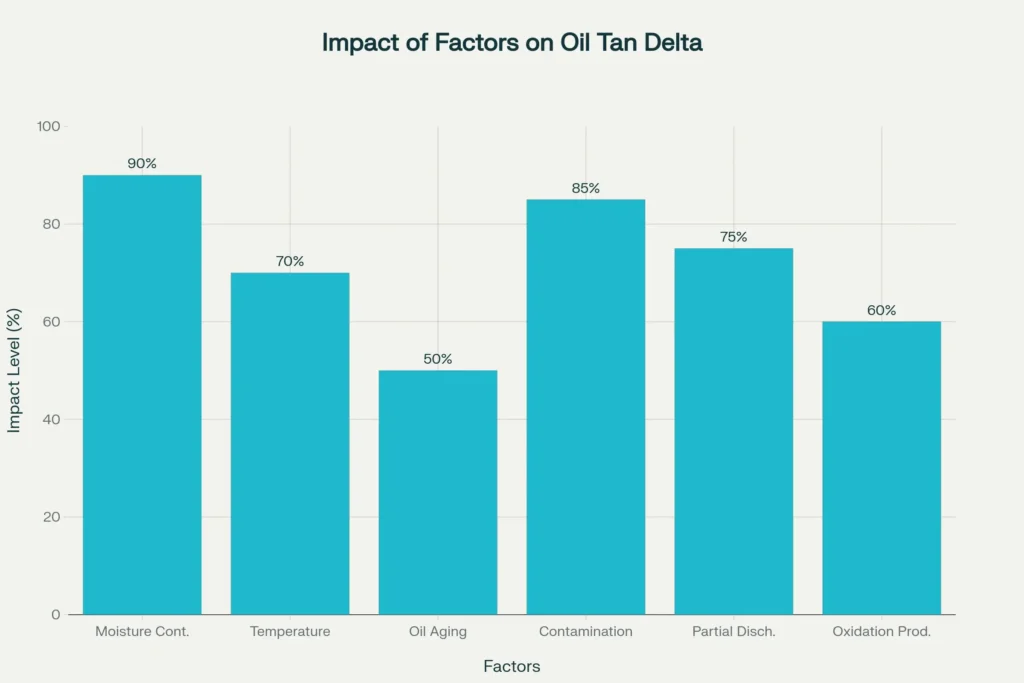

Moisture Contamination

Moisture represents the most significant single factor affecting tan delta values in transformer oil. Water molecules dramatically increase dielectric losses. Above 2.5% moisture content, tan delta rises steeply. Common moisture ingress sources include atmospheric breathing, leaking gaskets, and exposure during maintenance.

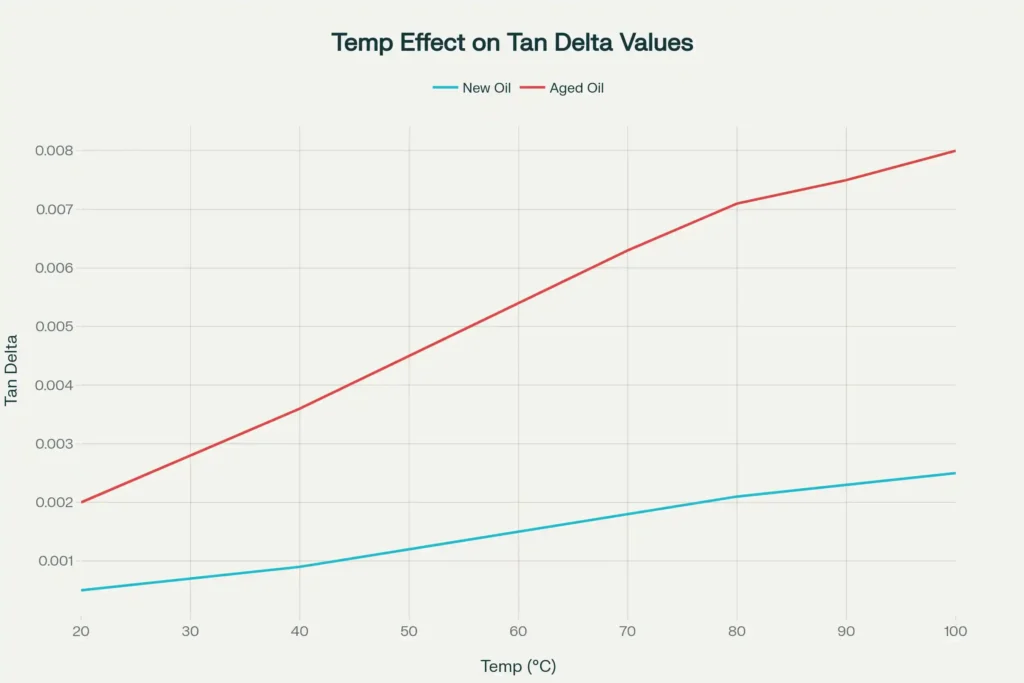

Temperature Effects

Tan delta values increase exponentially with temperature. New oil and aged oil both show rises, but aged oil’s tan delta values are higher and increase more rapidly with temperature.

Oil Aging and Oxidation

Oil aging through oxidation creates acids and polar products, gradually raising tan delta. Service-aged oil shows higher values even at the same moisture level.

Other Contamination Sources

Particles, acids, metal compounds, and thermal decomposition products can all increase tan delta. Each source adds to the overall measured value.

Interpreting Test Results

Normal vs. Abnormal Values

For transformer oil at 20°C, tan delta under 0.5% is excellent. Between 0.5%-0.7% is acceptable but should be monitored. Above 0.7%, oil quality is poor and needs attention. Stricter limits apply to ultra-high voltage transformers (2.0%), and lower voltage transformers may allow up to 4.0% in exceptional cases.

Trend Analysis

Rate of change matters more than one-time values. Tan delta should not increase more than 0.1% per year. Sudden increases signal serious issues such as moisture ingress.

Modern measurements also watch for increases with test voltage (“tip-up”), which indicates onset of ionization or partial discharge.

Correlation with Other Tests

Tan delta works best alongside:

- Moisture content by Karl Fischer titration

- Breakdown voltage (BDV)

- Resistivity

- Acidity measurement

- Dissolved gas analysis (DGA)

Practical Examples and Case Studies

Example 1: New Transformer Commissioning

- 100 MVA transformer: Tan delta at 25°C = 0.0004 (excellent)

- Oil is clean, dry, and free from contamination. This sets a baseline for future testing.

Example 2: Detection of Moisture Ingress

- Annual tan delta increased sharply after years of gradual rise. Moisture was confirmed, gasket fixed, oil filtered, and tan delta dropped again, proving effectiveness of maintenance.

Example 3: Bushing Fault Detection

- Abnormal tan delta readings for a particular bushing were traced to a defective unit and improved after replacement.

Example 4: Atmospheric Exposure Study

- Oil exposed to air showed tan delta rises of over 400% in two months alongside major drops in breakdown voltage, confirming the need for sealed systems.

Comparison: Oil Tan Delta vs. Overall Tan Delta Testing

| Aspect | Oil Tan Delta Test | Overall System Tan Delta Test |

|---|---|---|

| Test Voltage | 500V – 2kV AC | 10 kV – 12 kV AC |

| Measured | Oil sample only | Full insulation system |

| Sensitivity | High for oil contamination | Detects overall system problems |

| Test Duration | Quick (15-30 min) | Longer (1-2 hours) |

| Limitation | Can’t detect solid problems | Complex result interpretation |

Advantages and Limitations

Advantages

- Highly sensitive to contamination

- Non-destructive procedure

- Excellent for trending

- Thoroughly standardized

Limitations

- Strong temperature dependence and correction required

- Moisture detection limits at low levels

- Does not specify contaminant type

- Only assesses oil, not solid insulation

Best Practices and Recommendations

Testing Frequency

- New critical transformers: Baseline at commissioning, then every 1-3 years

- Critical power transformers: Annually (sometimes semi-annually as they age)

- Distribution transformers: Every 2-3 years

- After events, repairs, or oil handling: Always test

Sample Handling/Recording

- Use designated bottles, flush sampling valve, minimize air exposure, label and transport carefully

- Record all conditions for trending analysis

Safety

- Never test on energized transformers, ensure proper grounding, only qualified personnel should operate high voltage equipment, follow PPE and testing protocols.

Documentation

- Record in permanent transformer files, plot values and alert thresholds date-wise for trend analysis

- Compare against specifications and similar units

Conclusion

The tan delta test stands as an indispensable method for transformer oil quality assessment and power system reliability. With its sensitivity and clear standards, tan delta testing enables early action, reduces failure risk, and saves costs by optimizing maintenance. Integration of tan delta testing into routine preventive programs yields lifelong value for critical infrastructure.