Shaded pole induction motors represent one of the simplest and most economical types of single-phase induction motors available in the electrical engineering field. These motors, dating back to at least 1890, continue to play a crucial role in various low-power applications despite their inherent limitations. Shaded pole induction motors are self-starting single-phase AC motors that utilize a unique copper ring or shading coil to create the rotating magnetic field necessary for operation.

The fundamental principle behind these motors lies in their ability to create a phase shift in the magnetic field through electromagnetic induction, eliminating the need for complex starting mechanisms like capacitors or centrifugal switches. This makes them particularly attractive for applications requiring simple, reliable, and cost-effective motor solutions.

Construction and Design Features

Stator Configuration

The stator of a shaded pole induction motor employs a salient pole construction where the poles project toward the rotor armature. Typically designed with two or four poles for optimal performance, the motor’s speed is inversely proportional to the number of poles used. For a 50 Hz power supply, a two-pole motor achieves a synchronous speed of 3000 rpm, while a four-pole motor operates at 1500 rpm.

Each stator pole is divided into two unequal parts through a strategically placed slot cut approximately one-third of the distance from the pole edge. The smaller portion houses the shading coil – a short-circuited copper ring or band that forms a closed loop around this section. This copper band, also known as a shade band or shaded ring, acts as a transformer secondary winding and is fundamental to the motor’s self-starting capability.

The poles are constructed using laminated iron cores to minimize eddy current losses and increase structural strength. Each pole contains its own exciting coil, and the laminated construction ensures efficient magnetic flux distribution while reducing power losses.

Rotor Design

Shaded pole induction motors exclusively use squirrel cage rotors similar to those found in three-phase induction motors. The rotor bars are intentionally skewed at an angle of 60 degrees to reduce magnetic locking between the rotor and stator, thereby improving starting torque characteristics. Some designs implement V-type skewing for enhanced performance, though this increases manufacturing costs.

The rotor construction eliminates the need for commutators, brushes, collector rings, or centrifugal switches, contributing to the motor’s reputation for simplicity and reliability. This streamlined design reduces maintenance requirements and potential failure points.

Working Principle and Operation

Magnetic Field Generation

The operation of shaded pole induction motors relies on creating a rotating magnetic field from a single-phase AC supply through the clever use of electromagnetic induction principles. When alternating current flows through the stator winding, it produces a pulsating magnetic flux that links with both the shaded and unshaded portions of each pole.

The working principle can be understood by examining the behavior during different phases of the AC cycle:

Phase 1 (Flux Increasing): During the portion when flux begins to increase, an EMF is induced in the shading coil according to Faraday’s law. The resulting current in the shading coil opposes the change in flux per Lenz’s law, causing the flux in the shaded portion to weaken while the unshaded portion remains strong.

Phase 2 (Maximum Flux): When the flux reaches its maximum value and remains relatively constant, the rate of change approaches zero. Consequently, minimal EMF is induced in the shading coil, resulting in uniform flux distribution across the pole.

Phase 3 (Flux Decreasing): As the flux diminishes, the induced current in the shading coil reverses direction to maintain flux continuity. This strengthens the flux in the shaded portion while weakening it in the unshaded section.

Rotating Field Effect

The phase difference between the flux in the shaded and unshaded portions, combined with their spatial displacement of approximately 90 electrical degrees, creates what effectively amounts to a weak rotating magnetic field. This rotating field sweeps across the pole face from the unshaded portion to the shaded portion, providing the necessary starting torque for motor operation. The direction of rotation is always from the unshaded pole to the shaded pole, making standard shaded pole motors inherently unidirectional. Reversing the direction requires physically disassembling the stator and repositioning the shading coils, though some specialized designs incorporate switchable auxiliary windings for electrical reversal.

Performance Characteristics and Limitations

Torque-Speed Characteristics

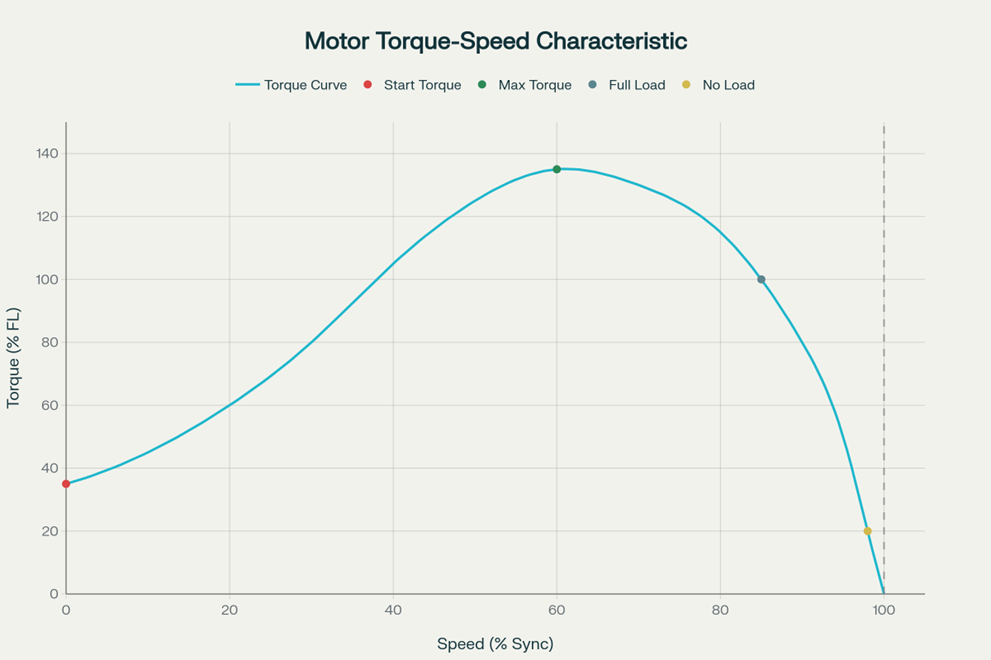

Shaded pole induction motors exhibit distinctive torque-speed characteristics that reflect their design limitations and intended applications. The starting torque typically ranges from 30% to 50% of full-load torque, which is significantly lower than other single-phase motor types. As speed increases, torque initially rises to reach a maximum (breakdown torque) at approximately 60% of synchronous speed before declining as the motor approaches its operating point.

The maximum torque is typically limited to 1.3 times the full-load torque, while the starting torque specification is only 0.3 times full-load torque. These characteristics make shaded pole motors suitable only for applications with light starting loads and minimal torque requirements.

Efficiency and Power Factor

One of the most significant limitations of shaded pole induction motors is their extremely low efficiency, typically ranging from 5% to 35%. This poor efficiency stems from several factors including high copper losses in the shading coil, suboptimal magnetic circuit design, and inherent power losses associated with the starting mechanism.

The power factor of these motors is also notably poor, typically ranging from 0.4 to 0.6. This low power factor, combined with high losses, results in increased energy consumption and limits the motor’s suitability to very small power applications.

Power Rating Limitations

Due to their inherent inefficiencies and performance limitations, shaded pole induction motors are manufactured only in small power ratings, typically ranging from 1/50 HP to 1/4 HP (approximately 15W to 190W). Some sources indicate that motors above 1/3 HP (250W) are uncommon, and larger applications require alternative motor designs with superior performance characteristics.

Advantages and Benefits

Despite their limitations, shaded pole induction motors offer several compelling advantages that ensure their continued relevance in specific applications:

Simplicity and Reliability

The simple construction with minimal moving parts contributes to exceptional reliability and longevity. The absence of centrifugal switches, capacitors, or complex starting circuits eliminates common failure points found in other single-phase motors.

Cost-Effectiveness

Manufacturing costs remain very low due to the straightforward design and minimal component count. This economic advantage makes shaded pole motors attractive for mass-produced consumer appliances where initial cost is a primary consideration.

Self-Starting Capability

The motors are inherently self-starting without requiring external starting mechanisms or user intervention. This feature is particularly valuable in applications where automatic operation is essential.

Robust Operation

Shaded pole motors can operate reliably even when the rotor is locked or stalled, as the primary and secondary phase currents remain relatively stable. This characteristic provides protection against damage during abnormal operating conditions.

Applications and Use

Household Appliances

Shaded pole induction motors find extensive use in household appliances where simplicity, low cost, and reliability are prioritized over efficiency. Common applications include:

- Exhaust fans and ventilation systems

- Table fans and small cooling fans

- Hair dryers and personal care appliances

- Refrigerator cooling fans

- Air conditioning circulation fans

Electronic Equipment

The motors are well-suited for electronic and office equipment applications:

- Record players and turntables

- Tape recorders and audio equipment

- Projectors and presentation devices

- Photocopying machines

- Electronic clocks and timing devices

Specialized Applications

Additional applications leverage the motor’s unique characteristics:

- Small pumps for water circulation

- Relays and switching mechanisms

- Display drives and positioning systems

- Oven fans for heat circulation

Comparison with Other Single-Phase Motors

Split-phase motors offer higher starting torque (100-175% of full-load) and better efficiency (60-75%) compared to shaded pole motors, but require centrifugal switches that add complexity and potential failure points. Capacitor start motors provide even higher starting torque (200-350% of full-load) and improved efficiency (70-80%), making them suitable for higher load applications.

Permanent split capacitor (PSC) motors achieve better power factors (0.85-0.95) and moderate efficiency (65-75%) while maintaining simplicity, though they sacrifice starting torque capability. In contrast, shaded pole motors offer the simplest construction with the lowest cost but provide the poorest performance in terms of efficiency and starting torque.

Conclusion

Shaded pole induction motors represent a mature technology that continues to serve important roles in specific applications despite inherent performance limitations. Their simplicity, reliability, and low manufacturing cost make them irreplaceable for certain consumer appliance and small device applications where efficiency is secondary to other considerations.

While their poor efficiency (5-35%) and low power factor limit their suitability to very small power applications, these motors excel in scenarios requiring automatic starting, minimal maintenance, and cost-effective operation. Understanding their characteristics, limitations, and proper applications enables electrical engineers to make informed decisions about motor selection for specific projects.