Induction motors represent the backbone of industrial automation and power systems, with approximately 90% of all industrial motors being three-phase induction motors. Among these, two primary classifications dominate the market based on rotor construction: squirrel cage induction motors and slip ring induction motors (also known as wound rotor motors). Understanding their fundamental differences, operational characteristics, and application-specific advantages is crucial for electrical engineers designing efficient motor-driven systems.

Motor Classification and Rotor Construction

Squirrel Cage Induction Motor Construction

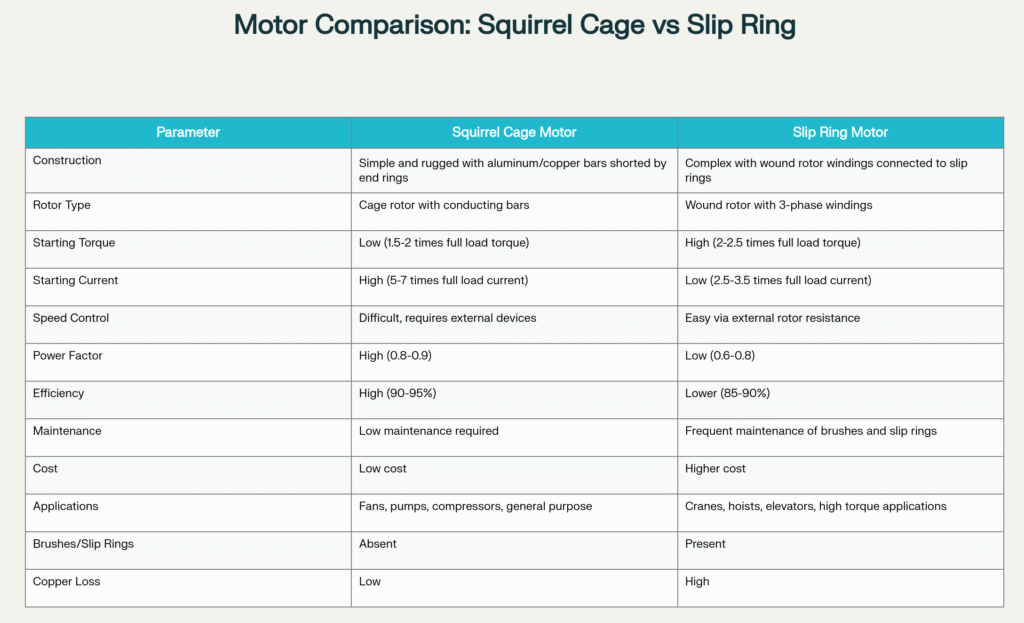

The squirrel cage induction motor derives its name from the distinctive rotor construction that resembles a squirrel cage. The rotor consists of a cylindrical laminated core with evenly spaced aluminum or copper bars placed axially around the periphery, permanently short-circuited at both ends by end rings. This simple yet robust construction eliminates the need for brushes, slip rings, or external connections to the rotor circuit.

The rotor bars are typically skewed or slanted rather than being parallel to the motor shaft. This skewing serves multiple purposes: preventing magnetic locking between stator and rotor teeth, reducing magnetic hum and slot harmonics, and improving starting torque characteristics. The skewed construction ensures smooth torque development and eliminates the possibility of cogging, where the motor fails to start despite full voltage application.

Slip Ring Induction Motor Construction

In contrast, the slip ring induction motor features a wound rotor with three-phase windings similar to the stator configuration. The rotor windings are connected in star formation, with the three terminals brought out through slip rings mounted on the motor shaft. Carbon brushes maintain constant contact with these slip rings, enabling external resistance connection to the rotor circuit.

This complex construction allows for external rotor resistance control, which fundamentally alters the motor’s starting and speed characteristics. The wound rotor typically has fewer turns per phase compared to the stator but uses heavier conductors to handle the induced currents.

Performance Characteristics and Operational Differences

Starting Performance Analysis

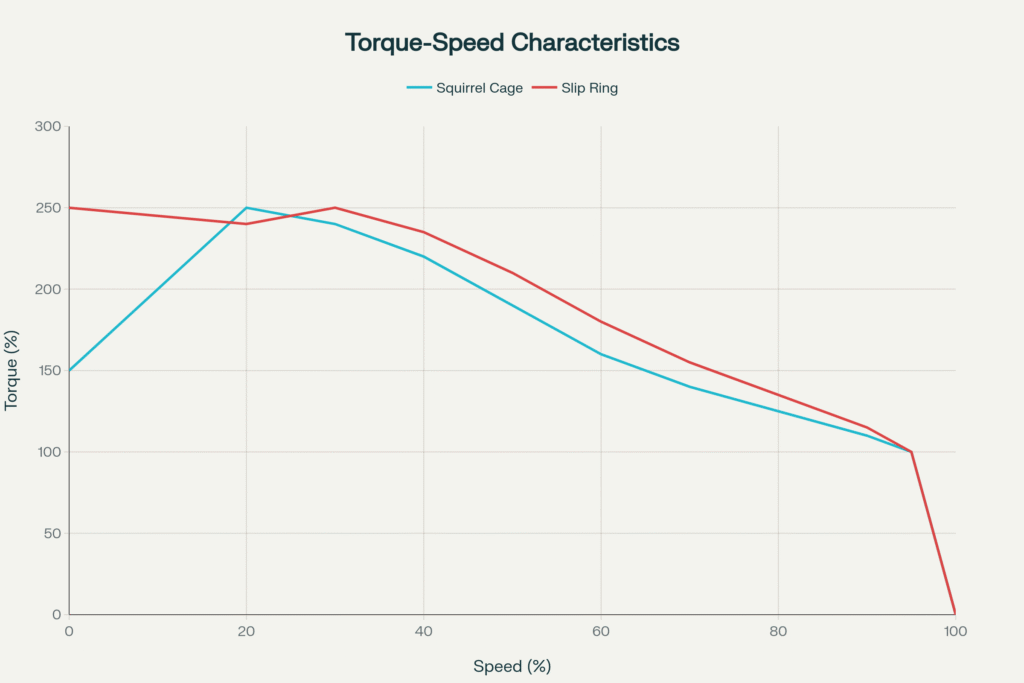

Starting Torque: The most significant operational difference lies in starting torque capabilities. Squirrel cage motors typically develop starting torque of 1.5-2 times the full load torque, while slip ring motors can achieve 2-2.5 times full load torque. This enhanced starting torque in slip ring motors results from the ability to insert external resistance in the rotor circuit during startup, improving the power factor of the rotor circuit.

Starting Current: Conversely, squirrel cage motors exhibit high starting currents of 5-7 times the full load current due to low rotor impedance at standstill. Slip ring motors demonstrate superior starting characteristics with reduced starting currents of only 2.5-3.5 times full load current, achieved through external rotor resistance that limits initial current flow.

Speed Control Capabilities

Squirrel cage motors offer limited speed control options due to the permanently short-circuited rotor bars. Speed variation typically requires external devices such as variable frequency drives, multi-speed configurations, or voltage control methods. The fixed rotor resistance characteristics make inherent speed control practically impossible.

Slip ring motors excel in speed control applications through rotor resistance variation. By adjusting the external resistance connected through slip rings, operators can achieve smooth speed control over a range of 50-100% of synchronous speed. This characteristic makes them ideal for applications requiring variable speed operation without sophisticated electronic controls.

Efficiency and Power Factor Considerations

Efficiency Comparison

Squirrel cage motors typically achieve higher efficiency ratings of 90-95% due to minimal rotor losses and absence of brush friction. The permanently short-circuited rotor bars ensure optimal current flow with minimal resistance losses during normal operation.

Slip ring motors demonstrate lower efficiency of 85-90% primarily due to higher copper losses in the rotor circuit and mechanical losses from brush friction. The presence of slip rings and brushes introduces additional losses that reduce overall efficiency, particularly during continuous operation.

Power Factor Analysis

The power factor characteristics differ significantly between the two motor types. Squirrel cage motors maintain a higher power factor of 0.8-0.9 at full load operation. This superior power factor results from the direct magnetic coupling between stator and rotor without external impedance elements.

Slip ring motors exhibit lower power factor characteristics of 0.6-0.8 due to the inductive nature of the wound rotor and external resistance elements. The additional reactance in the rotor circuit increases the phase angle between voltage and current, reducing the power factor.

Construction Details and Technical Specifications

Rotor Bar Construction and Materials

Squirrel cage rotors utilize either aluminum or copper conductor bars. Aluminum bars are die-cast directly into the rotor slots and end rings in smaller motors, while larger machines employ brazed copper bars for superior conductivity. The conductor material significantly impacts efficiency, with copper rotors offering approximately 4-7% higher efficiency than aluminum equivalents.

The laminated steel core construction minimizes eddy current losses through thin varnish-insulated laminations. Low-carbon, high-silicon steel provides optimal magnetic properties while maintaining electrical resistivity to reduce core losses.

Slip ring rotors feature insulated copper windings wound in slots similar to stator construction. The winding turns are fewer but use heavier conductors to accommodate the induced currents. The slip ring assembly typically consists of three rings made of brass or copper, providing reliable electrical connection to the external resistance circuit.

Air Gap Considerations

The air gap between stator and rotor significantly influences motor performance parameters including magnetizing current, power factor, overload capacity, and cooling characteristics. Larger air gaps increase overload capacity and improve cooling while reducing unbalanced magnetic pull and tooth pulsation effects. However, increased air gap also raises magnetizing current requirements, affecting power factor and efficiency.

Starting Methods and Control Systems

Squirrel Cage Motor Starting Methods

Several starting methods accommodate the high starting current characteristics of squirrel cage motors:

Direct-On-Line (DOL) Starting: The simplest method connects the motor directly to full supply voltage, suitable for motors up to 7.5 kW rating. While economical, this method subjects the motor and supply system to high inrush currents.

Star-Delta Starting: This widely used method initially connects stator windings in star configuration, reducing starting voltage to 58% of line voltage. After reaching approximately 80% speed, the connection switches to delta for full-voltage operation.

Auto-Transformer Starting: Employs a three-phase auto-transformer to provide reduced voltage (60-80% of supply voltage) during starting, then connects to full voltage as the motor accelerates.

Slip Ring Motor Starting Control

Rotor Resistance Starting represents the primary control method for slip ring motors. External resistance banks connected through slip rings provide high starting torque while limiting starting current. The resistance is gradually reduced as the motor accelerates, eventually short-circuiting the slip rings for normal operation.

This starting method offers several advantages: high starting torque for heavy loads, reduced starting current, and smooth acceleration characteristics. The external resistance can be manually controlled through rheostats or automatically managed through programmed resistance controllers.

Application-Specific Selection Criteria

Squirrel Cage Motor Applications

The robust construction, low maintenance requirements, and cost-effectiveness make squirrel cage motors ideal for general-purpose applications:

- Fans and Blowers: Constant speed operation with moderate starting torque requirements

- Centrifugal Pumps: Smooth torque characteristics match pump load curves effectively

- Compressors: Reliable operation in continuous-duty applications

- Conveyor Systems: Simple speed control requirements with standard load characteristics

Slip Ring Motor Applications

The superior starting torque and speed control capabilities make slip ring motors essential for demanding applications:

- Cranes and Hoists: High starting torque for lifting heavy loads with precise speed control

- Elevators: Smooth acceleration and deceleration with variable speed requirements

- Ball and Sag Mills: High-inertia loads requiring gradual speed buildup

- Large Pumps and Fans: Applications requiring soft-start capabilities and speed variation

Maintenance Requirements

Squirrel cage motors require minimal maintenance due to the absence of brushes, slip rings, and external connections. Routine maintenance includes bearing lubrication, vibration monitoring, and thermal inspection. The rugged construction typically provides 20-30 years of service life with proper maintenance.

Slip ring motors demand frequent maintenance attention, particularly for the brush and slip ring assembly. Regular tasks include brush replacement, slip ring cleaning and truing, resistance bank inspection, and electrical connection maintenance. The additional complexity increases maintenance costs and downtime requirements.

Conclusion and Selection Guidelines

The choice between squirrel cage and slip ring induction motors depends primarily on application-specific requirements balancing performance, cost, and operational factors. Squirrel cage motors excel in constant-speed, general-purpose applications where simplicity, reliability, and low maintenance are paramount. Their dominance in industrial applications reflects the robust design, cost-effectiveness, and minimal maintenance requirements.

Slip ring motors remain essential for applications demanding high starting torque, precise speed control, or soft-starting capabilities. Despite higher initial costs and maintenance requirements, they provide unique advantages for heavy-duty, variable-speed applications where their superior characteristics justify the additional complexity.