Winding resistance measurement is a critical diagnostic test performed during transformer commissioning and maintenance to assess the electrical integrity of transformer windings. This test identifies faults such as loose connections, broken strands, deteriorated tap changer contacts, and internal winding damage.

By measuring the DC resistance of transformer windings and comparing results with factory test values or between phases, engineers can detect abnormalities that might otherwise remain undetected until catastrophic failure occurs.

What is Winding Resistance Measurement?

Winding resistance refers to the ohmic resistance of a transformer’s primary and secondary windings. This resistance represents the opposition to direct current flow through the conductor material and is influenced by factors such as the copper or aluminum conductor material, the cross-sectional area of the conductors, the length of the winding, and most importantly, the condition of the connections and the integrity of the conductor itself.

Winding resistance measurements are obtained by passing a known DC (direct current) through the winding under test and measuring the voltage drop across the terminals using Ohm’s Law: R = V/I. This method is preferred over AC measurements because it eliminates the complicating effects of the winding’s inductance, which can introduce errors in resistance determination.

Why is the Winding Resistance Test Important?

The winding resistance test serves multiple critical purposes in transformer diagnostics. First, it identifies winding faults such as shorted turns, broken strands of conductor, and loose connections that cannot be visually observed. Second, it provides a baseline measurement for future trending during maintenance cycles, allowing engineers to detect degradation over time. Third, it helps verify that all winding connections are secure and properly assembled according to design specifications. Finally, the test can reveal problems in tap changers and load-tap-changing mechanisms by measuring resistance across different tap positions.

Purpose and Scope of the Test

This test is performed on power transformers, distribution transformers, and special transformers during the pre-commissioning phase before the transformer is energized for the first time. It is also an essential routine maintenance test performed periodically (often annually) to verify the continued integrity of the winding connections and to detect any deterioration caused by thermal stress, contamination, or mechanical damage.

The expected deviation for field winding resistance tests should not exceed 5.0% of the factory test value, recognizing that field conditions make it unlikely to achieve the precision of controlled laboratory measurements.

Pre-Commissioning Procedures for Winding Resistance Measurement

Equipment and Preparation

Before conducting the winding resistance test, ensure the following preparations are complete:

Equipment Required:

- DC winding resistance test set (preferably with automatic measurement capability)

- DC voltage source (10-40 VDC recommended, with compliance voltage above 40 VDC preferred)

- Temperature measurement device (temperature probe or infrared thermometer)

- Analog multimeter for continuity checks during tap changing operations

- Leads and test cables with proper insulation ratings

- Safety equipment including insulated gloves and warning signs

- Connection diagram and nameplate specifications

Pre-Test Requirements:

- Isolate and de-energize the transformer completely

- Allow adequate time for the transformer to cool to ambient temperature

- Visually inspect all winding terminals and tap changer contacts for cleanliness and corrosion

- Verify all connections are tight and secure

- Ground the transformer tank and all non-test windings to earth for safety

- Record ambient temperature and oil temperature (if applicable) before testing

Selecting the Appropriate Test Current

Test current selection is critical for obtaining accurate measurements without introducing errors. According to IEEE C57.152 and IEC 60076 standards, the DC test current should be selected based on the following guidelines:

- Current range: 0.1% to 10% of the winding’s rated current

- Minimum current: At least 1 ampere for HV windings (preferably 1-3 A)

- Maximum current: Not exceeding 10% of rated winding current; for LV windings, particularly those with very high current ratings, currents up to 5% of rated current may be used

- Core saturation consideration: Sufficiently high current should be used to saturate the transformer core, reducing inductive effects and stabilizing readings more quickly

- Heating consideration: Large test currents may cause unwanted heating of the winding, changing its temperature and resistance, introducing measurement errors

Practical selection:

- For high-resistance windings (above 100 mΩ): Use 10 A or less

- For low-resistance windings (below 100 mΩ): Use 20-50 A for improved accuracy

- Always select the highest current available that does not exceed the 10% limit to minimize measurement uncertainty

Temperature Considerations

Temperature compensation is essential for accurate interpretation of winding resistance results. Resistance varies directly with temperature according to the relationship:

The winding resistance should preferably be carried out when the difference in the top and bottom temperature of the winding (temperature of oil in steady-state condition) is equal to or less than 5°C. This ensures thermal equilibrium and prevents measurement variations due to thermal gradients within the winding.

Temperature measurement procedures:

- Measure the winding temperature directly using a temperature probe placed in the transformer oil adjacent to the winding

- For transformers with thermometers, record the oil temperature reading

- Note the ambient temperature if measuring without immersion

- Wait for temperatures to stabilize before conducting measurements

- Record the exact temperature at the moment of resistance measurement

Standard Test Procedures

Step 1: Configure Test Connections

For Star (Wye) Connected Windings:

- Measure resistance between each line terminal and neutral terminal

- Connections: L1-N, L2-N, and L3-N

- This provides three individual phase resistance measurements

For Delta Connected Windings:

- Measure resistance between pairs of line terminals

- Connections: A-B, B-C, and C-A (or R-Y, Y-B, and B-R using color designations)

- Since individual winding resistance cannot be measured directly in delta connection, calculate using the formula:

Resistance per winding = 1.5 × Measured value

For Auto-Transformer Windings:

- For star-connected auto-transformers, measure resistance between HV terminal and IV terminal, then between IV terminal and neutral

- The tap changer should be changed from contact to contact (not to multiple positions at once) with continuity checks performed using an analog multimeter

Step 2: Establish Test Connections

- Connect the current input leads to the winding terminals being tested

- Connect the voltage measurement leads beyond (outside of) the current leads to eliminate lead resistance from the measurement (4-wire Kelvin method)

- Ensure all other winding terminals not under test are properly grounded

- Ground the transformer tank and core to earth

Step 3: Apply DC Current and Allow Stabilization

- Start with the lowest appropriate test current range

- Gradually increase the test current to avoid sudden magnetization transients

- Wait for current to stabilize completely before recording any readings

- For small transformers, stabilization may take only a few seconds

- For large transformers, particularly those with delta-connected windings, stabilization may require several minutes

- The longer stabilization time in large transformers results from the higher inductance, which causes resistance values to “drift” until the magnetic core reaches saturation

Step 4: Record Measurements

- Once readings have stabilized, record the voltage and current values

- Note the exact winding temperature at the moment of measurement

- Record all readings in a test log with date, time, transformer identification, and test conditions

- Take multiple measurements (at least two per winding) to verify consistency

- If results vary significantly between repetitions, investigate possible connection problems before proceeding

Step 5: Temperature Correction to 75°C Standard

All field measurements must be corrected to a standard reference temperature of 75°C (or 85°C for certain transformer types) for comparison with factory test data and for diagnostic trending.

The temperature correction formula is:

\( R_{75} = R_t \times \frac{(234.5 + 75)}{(234.5 + t)} \)

Where:

- \(R₇₅\) = Resistance corrected to 75°C

- \(Rₜ\) = Resistance measured at field temperature (in ohms)

- \(t\) = Actual measured winding temperature during test (in °C)

- \(234.5\) = Temperature coefficient for copper windings (use 225 for aluminum windings)

Example calculation:

If a winding measures 0.0394 ohms at an oil temperature of 26°C:

\( R_{75} = 0.0394 \times \frac{(234.5 + 75)}{(234.5 + 26)}\)

\( R_{75}= 0.0394 \times \frac{309.5}{260.5} \)

\( R_{75}= 0.0394 \times 1.188 \)

\( R_{75}= 0.0468\, ohms \)

Step 6: Calculate Three-Phase Sum Resistance

After measuring and correcting all individual winding resistances:

For Star Connection:

Add the three phase-to-neutral resistances directly:

\(R_{total} = R_{L1N} + R_{L2N} + R_{L3N}\)

For Delta Connection:

Add the three line-to-line resistances and divide by 2:

\(R_{total} = (R_{AB} + R_{BC} + R_{CA}) / 2\)

Then apply 1.5 multiplication factor if calculating individual winding resistance

Step 7: Compare Results Against Acceptance Criteria

Acceptable Limits:

The resistance value obtained should be compared using the following criteria:

- Comparison between phases: Resistance values of the three phases should be within 1% of each other at the same tap position

- Comparison with factory test value: Field measurements should be within 5% of the original factory test value (accounting for temperature differences)

- Comparison with previous field measurements: Changes exceeding 2% from the previous field test typically indicate winding deterioration or connection problems

- Measurement across all tap positions: For transformers with load-tap changers (OLTC), winding resistance should remain relatively consistent across all tap positions; significant variations indicate tap changer contact degradation or positioning problems

Special Considerations for Auto-Transformers

Auto-transformers require special attention when performing winding resistance tests because the primary and secondary windings are not electrically isolated. For star-connected auto-transformers:

- The resistance of the HV side is measured between the HV terminal and IV (isolated neutral/intermediate voltage) terminal

- A second measurement is taken between the IV terminal and the neutral point

- For delta-connected auto-transformer tertiary windings, measure between pairs of line terminals as with standard delta connections

- Record the tap position carefully, as auto-transformer tap changers operate differently than conventional transformer tap changers

- Perform continuity checks between HV and neutral at all tap positions during tap changing operations

Testing Across Multiple Tap Positions

For transformers equipped with load-tap-changing (OLTC) mechanisms, winding resistance measurements are performed across multiple tap positions to assess the condition of the tap changer contacts:

- Measure winding resistance from tap position 1 through position 17 (for OLTC mechanisms typically rated for 17 positions)

- Then measure in reverse order from position 17 back to position 1 (using only 2-3 intermediate steps for efficiency)

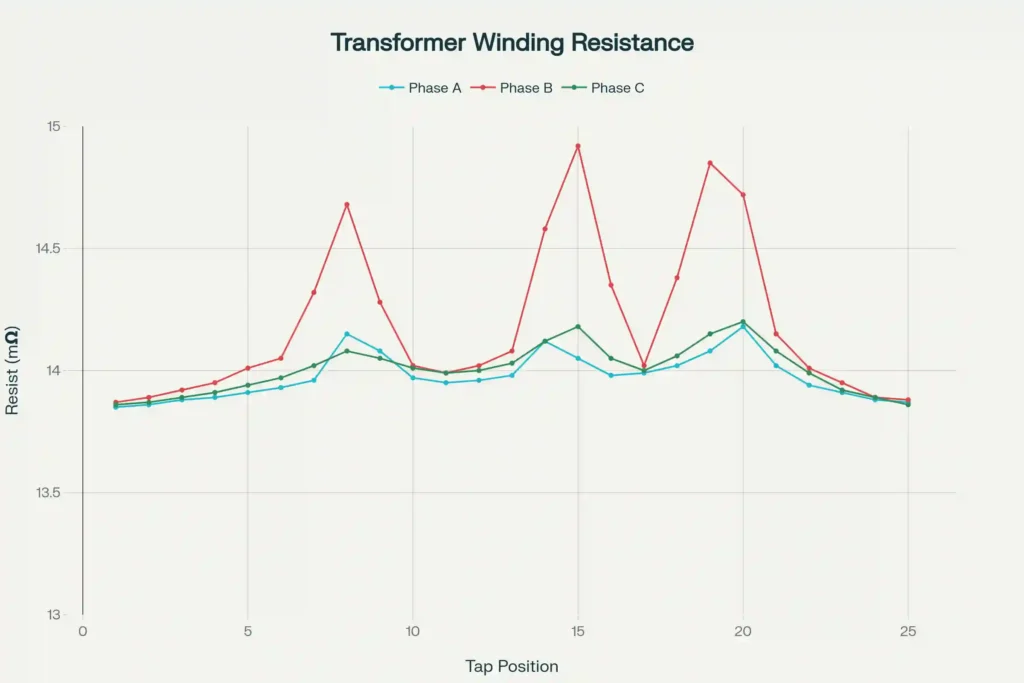

- Plot the resistance values across all tap positions on a graph for analysis

- Smooth, continuous resistance curves indicate healthy tap changer operation

- Sharp spikes or discontinuities in resistance indicate contact problems, excessive wear, or deposits on switching contacts

- Compare resistance values across all three phases; significant phase-to-phase differences at the same tap indicate potential phase-selective contact degradation

During tap changing operations, perform continuity checks between HV and neutral terminals using an analog multimeter while changing the tap, ensuring continuous electrical connection throughout the switching sequence.

Core Demagnetization After Testing

The winding resistance test must preferably be carried out last after completion of all other low-voltage (LV) tests, as the DC current injection required for saturation leaves the transformer core significantly magnetized. If the core is not properly demagnetized before energizing the transformer, residual magnetization can:

- Cause inrush currents significantly higher than normal, potentially damaging distribution system protection devices

- Create harmonic distortion in the transformer’s magnetizing current

- Affect other tests such as magnetizing current and magnetic balance tests, leading to misleading results

- Damage sensitive protective relays or meters connected to the transformer

Demagnetization procedure:

- After completing all winding resistance measurements, apply a decreasing AC voltage at power frequency (50 or 60 Hz) to the transformer winding

- Start with a voltage slightly higher than the normal operating voltage

- Gradually reduce the voltage in steps of 10-50% at each half-cycle

- Continue until the voltage reaches zero, at which point the residual magnetization is virtually eliminated

- Modern test equipment includes automatic demagnetization functions that implement this procedure electronically

- Verify successful demagnetization by checking that magnetizing current measurements return to expected values

Interpretation of Test Results

Normal Results

Normal winding resistance test results show:

- Phase-to-phase consistency: Resistance values within 1% of each other

- Compliance with standards: Values within manufacturer specifications or within 5% of factory test values (when temperature-corrected)

- Smooth tap changer curves: For OLTC transformers, a smooth progression of resistance values across all tap positions with no sudden discontinuities

- Stable measurements: Once stabilization is complete, readings remain constant within 0.1% over time

Abnormal Results Indicating Winding Problems

Loose connections or broken strands manifest as:

- Higher than normal resistance in one or more phases

- Phase-to-phase resistance variations exceeding 2-3%

- Abrupt increase in resistance compared to factory baseline or previous field measurements

Shorted turns or interlayer faults produce:

- Lower than expected resistance in affected phase

- Unusual consistency of low resistance (resistance shouldn’t drop suddenly)

- May not always be evident in DC resistance measurement if the shorted turns don’t significantly change total winding resistance

Tap changer contact deterioration appears as:

- Variable resistance across tap positions in OLTC transformers

- Sharp resistance spikes at certain tap positions indicating arcing or contact erosion

- Phase-to-phase variation in the resistance-versus-tap-position curve, with affected phases showing abnormal spikes

- Asymmetric curves where one phase shows significantly different resistance progression than the others

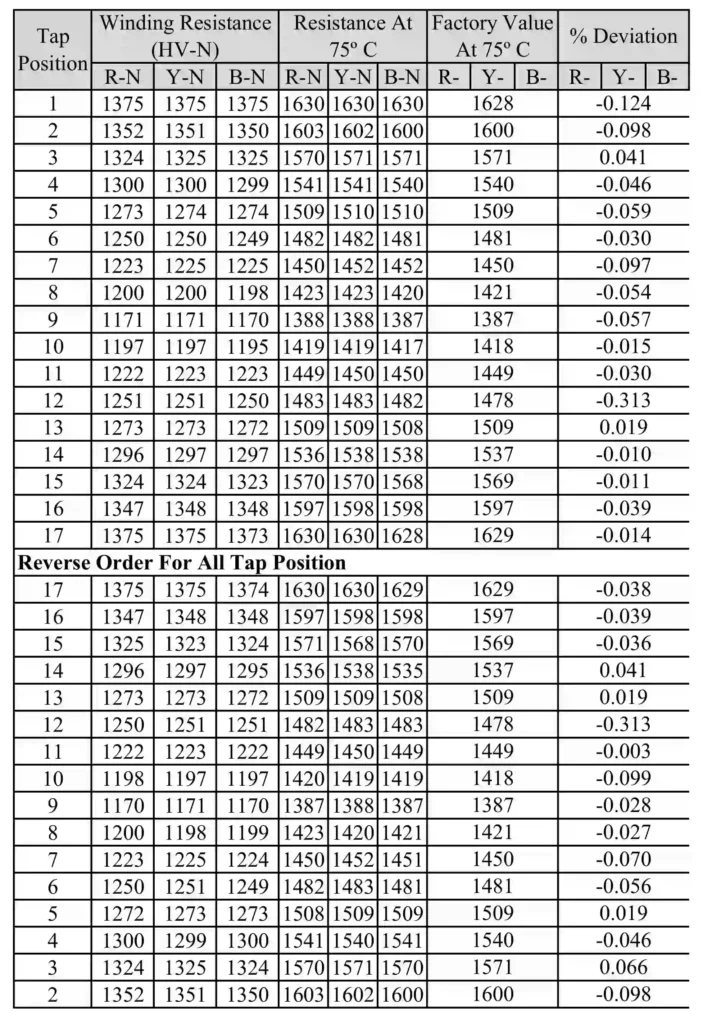

Transformer Winding Resistance Real Field Test Data Example

The photograph below shows actual transformer winding resistance test results recorded by me during a pre-commissioning field test of a 20 MVA 132/33 kV Transformer.

Transformer Winding Resistance Temperature Correction Calculator

Conclusion

The winding resistance measurement test represents one of the most critical diagnostic procedures in transformer commissioning and maintenance. By carefully following prescribed test procedures, selecting appropriate test currents, measuring and correcting winding temperatures, and properly interpreting results, engineers can reliably assess winding integrity and detect problems before they escalate into service failures.

Also Check:

- Capacitance and Tan Delta Test of Transformer Windings

- Capacitance and Tan Delta Test of Transformer Bushings

- How to Perform a Polarity Test on a Single Phase Transformer

- How to Do Vector Group Test of Transformer

- Floating Neutral Point Measurement Test of a Transformer

- Sweep Frequency Response Analysis Test of Transformer

Frequently Asked Questions

DC current is used because it eliminates the complicating effects of the winding’s inductance, which would introduce errors in resistance determination. AC measurements cause the resistance value to appear to “drift” before stabilizing, making accurate readings difficult. DC measurement provides clean, stable readings by avoiding inductive effects.

Winding resistance testing should be performed during the pre-commissioning phase before the transformer is energized for the first time, and as part of routine maintenance testing (typically annually). The test should preferably be conducted last after all other low-voltage tests to allow proper core demagnetization before service.

According to IEEE C57.152 and IEC 60076 standards, the DC test current should be between 0.1% to 10% of the winding’s rated current. The minimum current is at least 1 ampere for HV windings (preferably 1-3 A).

The resistance value “drifts” initially due to the winding’s inductance, which magnetizes the transformer core. Small transformers stabilize in seconds, but large transformers—particularly delta-connected windings—can take several minutes because of their higher inductance.

Resistance varies directly with temperature for copper and aluminum conductors. All field measurements must be corrected to the standard reference temperature (75°C) to accurately compare with factory test data and historical measurements. Without temperature correction, field results cannot be meaningfully compared across different testing conditions.

Phase-to-phase resistance variation should be within 1% of each other at the same tap position. Field measurements should be within 5% of the original factory test value (after temperature correction). Changes exceeding 2% from the previous field measurement indicate potential winding deterioration.

Higher than normal resistance in one or more phases typically indicates loose connections, broken conductor strands, or poor winding assembly.

For star-connected auto-transformers, measure resistance between the HV terminal and IV (intermediate voltage) terminal, then between the IV terminal and neutral. For delta-connected tertiary windings, measure between pairs of line terminals.